Juice and milk homogenizer

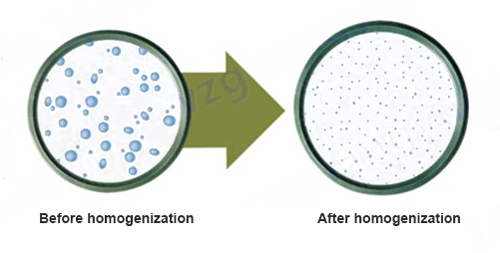

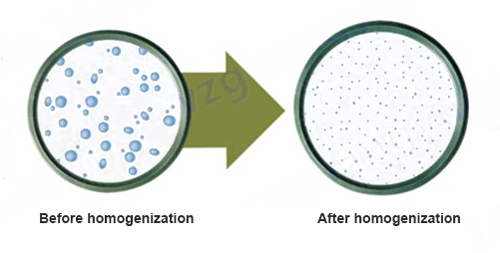

Homogenization is a common technology in food and chemical industry. It can make the crude and turbid liquid mixture or liquid-solid mixture into fine, uniform and stable emulsion, or liquid with solid dispersion.

Homogenization is carried out by homogenizers. It is an important equipment in food, drink, and dairy industry. The homogenizer is made of stainless steel. The raw materials are packed in Sterile homogenous bags, without contact with the apparatus. The homogenizer doesn't have high-temperature or sterilization treatment, so it doesn’t cause damage to the raw materials.

Application of high-pressure homogenizer

Homogenizer is widely applied in the field of food, dairy, beverage, pharmaceutical, chemical, biological technology and scientific research. In food and drink industry, homogenizer is usually used to process UHT milk, pasteurized milk, yogurt, milk drinks, soy milk, fruit juice, peanut milk, etc.

-

For fruit juices, homogenization can make the grains finer, prevent layering, prolong shelf life, save the use of additives.

-

For milk and dairy products, it can prevent the floating and cohesion of fat globules, improve the taste and prolong service life.

-

For chemical products, it can refine and emulsify the product, unify the viscosity, make the texture more smooth, the color more bright. Improve the stability of materials, so that they are easier to apply.

-

For cosmetic products, it can make the texture more smooth, the color brighter, the ingredients more uniform and easier to absorb.

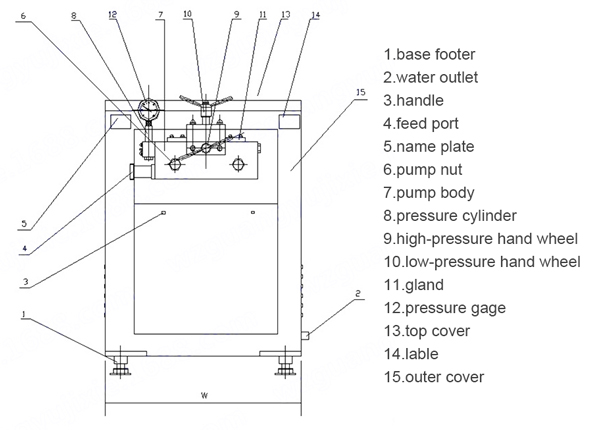

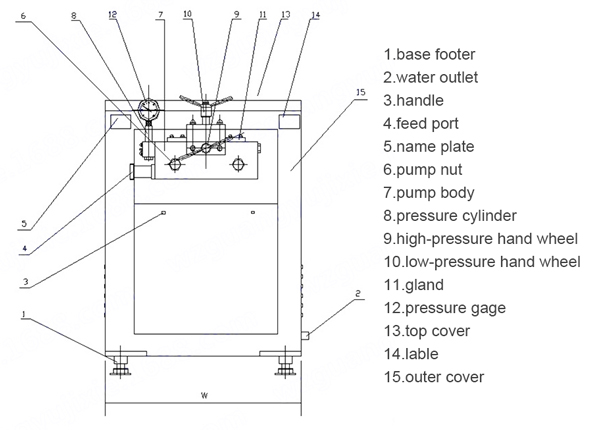

The working principle of high-pressure homogenizer

The raw materials are sent to the homogenizing valve by the reciprocating motion of three plungers. When the raw materials pass through the micro clearance between the valve disc and seat, it is under the composite force of turbulence, hole, and shear. Then the crude and turbid emulsion is processed into fine, uniform and stable liquid or liquid with solid dispersion.

The average fineness of the emulsion is under 1um, the grain size of solid dispersion is under 2um. The homogenized materials has such advantages: higher stability, long preservation time, faster reaction time, saving additives, promote body absorption. It is widely applied in food, health care products, cosmetics and other fields.

Features of juice and milk homogenizer

-

The homogenizer can make the unmixed solid, liquid and gas uniformly distributed and refined instantaneously. By the high-frequency line shear and the circulation of dispersing emulsifier, the raw materials become high-quality and stable product.

-

Supported by bearings, assembled by modular, with no pollution to the raw materials. It is applicable to materials with high requirement on the cleanliness, such as food, chemicals, cosmetics.

-

High-pressure homogenizer is used in the production of emulsion, glue, juice, slurry. Homogenization can prevent or reduce the layering of liquid, improve the appearance, and make the color more bright, the flavor more strong and the taste more thick.

-

It can realize the distribution, emulsification, homogenization, dissolution, and reaction of liquid materials with different viscosity. It can make your production more convenient.

-

The complete machinery is covered with stainless steel shell. The exterior is clean, exquisite, sanitary and safe.

-

Adopts bevel gear, low speed transmission. Low noise, stable running, reliable performance. The transmission part adopts unique splash oil delivery method, which can realize lubricating of every parts.

-

The valve seat adopts double-side design, which can double the working life. The homogenization valve, one-way valve, and plunger are made of alloy steel. They are resistant to abrasion and impact, with long working life.

Specifications of juice homogenizer

|

Model |

Rated flow (l/h) |

Rated pressure(Mpa) |

Working pressure(Mpa) |

Power(Kw) |

|

MGJ500/25 |

500 |

25 |

20 |

5.5 |

|

MGJ500/60 |

500 |

60 |

50 |

11 |

|

MGJ1000/25 |

1000 |

25 |

20 |

7.5 |

|

MGJ1000/40 |

1000 |

40 |

35 |

15 |

|

MGJ2000/25 |

2000 |

25 |

20 |

15 |

|

MGJ2000/40 |

2000 |

40 |

35 |

30 |

|

MGJ5000/25 |

5000 |

25 |

20 |

45 |

|

MGJ5000/40 |

5000 |

40 |

35 |

55 |

|

MGJ10000/35 |

10000 |

35 |

28 |

110 |

|

MGJ10000/40 |

10000 |

40 |

32 |

132 |

How to choose a suitable type of homogenizer

-

Choose the pressure you need according to the process requirement and the effect you want to achieve.

-

Confirm the production every hour according to the demand and the production capacity of relative equipment and juice processing machinery.

-

The products in the table above are all production-type high-pressure homogenizer, not laboratory type homogenizer.

-

If you have decide the type you want, please contact us in the form below. If you still have questions, welcome to send us inquiry!

Get in Touch Now!