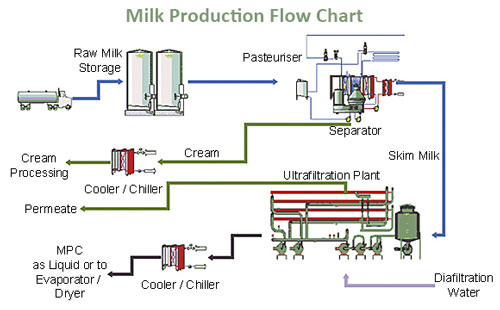

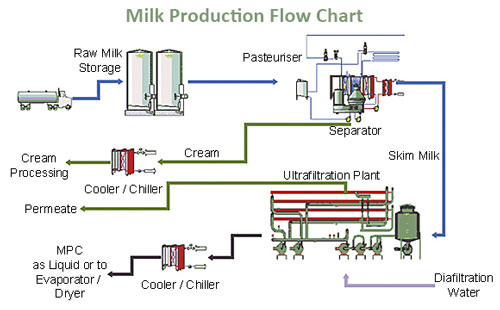

Milk production line

The milk production process includes: raw milk collection, filtration, preheat, homogenization, sterilization, cooling, and filling. The milk production equipment includes refrigerated milk storage tank, joint filter, plate heat exchanger, homogenizer, plate pasteurizer, cooling tank, CIP cleaning system.

Milk production technology types

Generally, there are 2 kind of milk in the market. One is UHT milk. To ensure long time preservation and long distance transportation, it is processed by ultra heat treatment: to heat up the milk to 75-90℃ and last 15-16s. With short sterilization time, the production efficiency is high. The key of UHT technology is to eliminate bacteria and minimize shelf life. UHT milk has over half a year of shelf life, but it also sacrifice some nutrition.

The other is pasteurized milk. To preserve the milk nutrition as much as possible, some milks are processed by pasteurization technology: to heat up the milk to 62-65℃ and last for 30 min. With this technology, it can eliminate 97.3%~99.9% bacteria in milk. There remain some thermophiles and heat resistant bacteria and spores, but they are most lactic acid bacteria that benefit human body. Besides, pasteurized milk has high requirement on the milk source.

Milk collection and storage

Refrigerated milk storage tank is used in milk collection center, pasture, diary plant, food factory, dairy farmers for milk collection, cooling and storage. Refrigerated milk storage tank is an important support equipment in mechanized milking pasture, as well as hand milking pastures. Besides, it can cool and store other liquid materials so as to preserve them from bacterial reproduction.

Milk filtration

Milks are filtrated by joint filters. It adopt 2 three-way ball valves to install 2 single-drum filter in one base. It allows you to clean one filter without shutting down the machine, so as to ensure continuous work. This joint filter can work with one drum, as long as you remove the common base.

The joint filter adopts stainless steel filter element and cellular degreased fiber cotton. It can filter out particles whose diameter is larger than 1μm. It adopt single-layer stainless steel welding structure, with both inside and outside surface polished.

At the top of the filter drum is installed with air vent valve. The pipe joints adopt expansion connection, which has passed 0.3Mpa water pressure test. The thread plug of the three-way ball valves are flexible to open and shut. The whole joint filter has compact structure, simple operation, and is easy to maintain.

Milk preheating

Plate heat exchanger is composed of a series of piled up corrugated sheet of metal. These metal sheets forms thin rectangular channels that heat up the milk flowing through it.

Plate heat exchanger is the ideal equipment for heat transmission between liquid and liquid or liquid and vapor. It features high heat exchange efficiency, low heat loss, compact structure, less space demand, easy installation and cleaning, wide application, long service life.

With the same pressure loss, its heat transfer coefficient is 3-5 times higher than tubular exchanger. The floor space is only 1/3 of the tubular heat exchanger. The heat recovery rate is up to 90%.

Milk homogenization

The milk homogenizer is used for the ultrafine dispersing and emulsification of various liquid. It has stable and continuous running, low noise, easy cleaning, and high flexibility.

Homogenization is carried out after preheating, when the milk temperature reach up to 60~65℃. The homogenization has 2 steps: the first step adopt high pressure (16.7~20.6MPa) to crush the fat globules, the second step adopt low pressure (3.4-4.9MPa) to disperse the crushed small fat balls to prevent blocking.

Milk pasteurization

Plate pasteurizer adopt UHT technology. It can heat up the milk to 135℃-140℃ for 3-5s. It can eliminate bacteria within very short time and preserve most of the nutrition. It applies to milk, juice, tea and other fluid without high fiber or high viscosity.

The plate pasteurizer features high heat recovery rate, energy efficiency, compact structure, simple operation, easy maintenance. The major components are material pump, balance bucket, hot water system, temperature control and record device, electric control system. It has full-automatic control type, equipped with PLC controller, touch screen display.

Get in Touch Now!