Vacuum degasser for fruit juice

Vacuum degasser is also known as vacuum deaerator, vacuum degasifier. It is used to eliminate the air (oxygen) in fruit juice, milk and other drinks. Degassing can inhibit the browning and the oxidation of pigment, vitamins, fragrant component and other substance, so as to preserve the drink quality, and prolong shelf life.

Degassing process also has other functions. It can remove the gas attached to the suspending particles in the fruit juice and prevent them from floating. It can prevent blister during high-temperature sterilization and filling. It can improve the appearance of the drink, and reduce its corrosion to the inner wall.

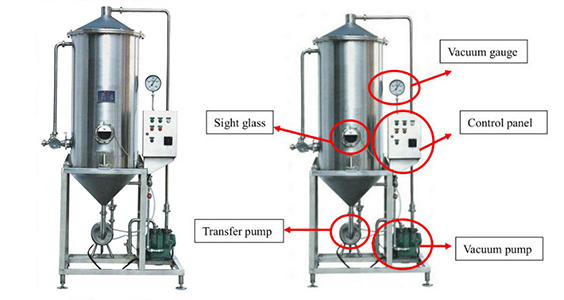

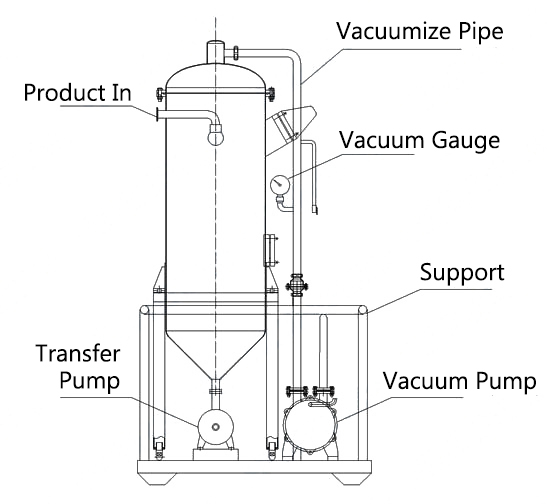

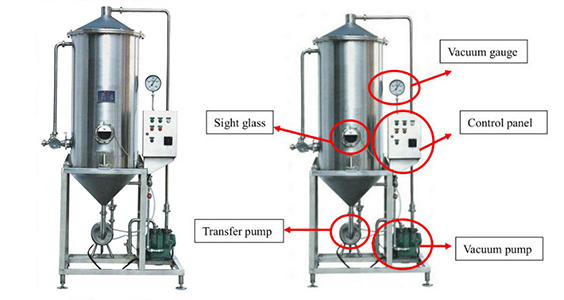

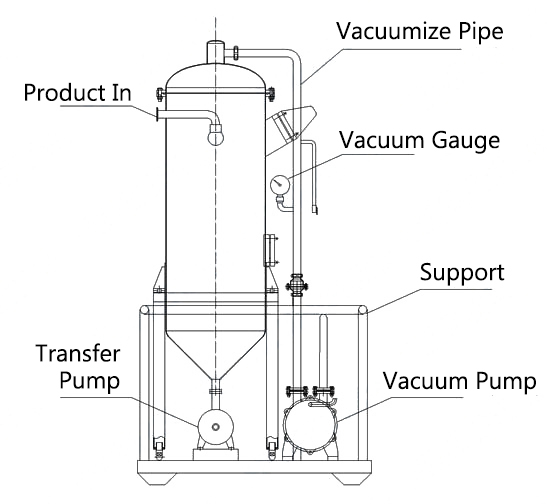

Structure of Vacuum degasser

The vacuum degasser can be divided into 4 parts, vacuum degassing device, vacuum pump, transfer pump, and control panel. The component parts are tank, head cover, check valve, control valve, sprayer nozzle, eyehole, etc.

All parts that connect with fruit juice adopts superior stainless steel and food-grade Silicone rubber.

Specifications of vacuum deaerator

|

Model |

VD-1.5 |

VD-2.5 |

VD-5 |

VD-10 |

|

Capacity(T/h) |

1.5 |

2.5 |

5 |

10 |

|

Power(Kw) |

2.2 |

2.2 |

4 |

15 |

Vacuum degree

(Mpa) |

-0.08~-0.0906 |

AGICO is a professional fruit juice processing machinery manufacturer and supplier. We can provide vacuum degasser and other equipment in fruit juice production line. Welcome to contact us through the button on the right side and fill out the form on the bottom.

Features of vacuum degasser

-

Greatly shorten the evacuation time after the initial water injection, which facilitate the initial commissioning and running of the system.

-

Eliminate the gas in the degassing system, prevent air blockage, and ensure continuous and stable work.

-

By eliminating the cavitation of water pump, it can lower the noise during operation.

-

As the oxygen in the liquid has been removed, It can relieve the corrosion to the system and prolong the working time of the equipment.

-

As the gas in the liquid has been removed, there will be no gas attached to the surface of the heat-exchanger. So the heating supply efficiency has been improved.

-

The working time and intervals of the vacuum degasser can be adjusted according to your needs.

-

The capacity of a vacuum degasser is as high as 150 m3. Several sets can be used in parallel.

-

The equipment is easy to install. It can realize full automatic work. It is safe, stable, and easy to maintain.

How to operate a vacuum deaerator?

Under the guidance of instruction book, turn on the vacuum pump to draw out the air in the tank. At the same time, the raw materials are sucked into the tank. You can control the feeding speed with the control valve and observe it through the eyehole. When the liquid materials rise up to certain level, and the vacuum degree in the tank reach the requirement, you can draw out the materials through the outlet. Keep the in and out of the raw materials stable and the production can continue.

Cautions for use

-

Open up the top cover and clean the inside of the tank with warm water or caustic soda solution every time before using.

-

Keep every sealing part in right condition and prevent air leakage.

-

Check the diaphragm pressure gauge regularly to keep it accurate.

Get in Touch Now!