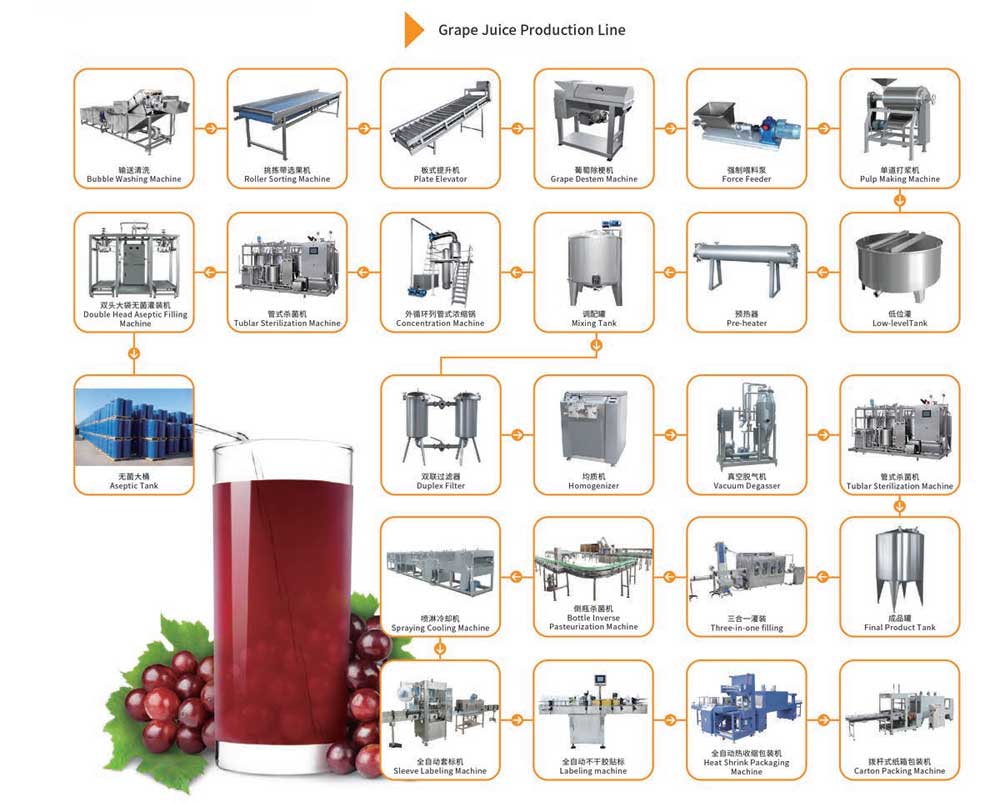

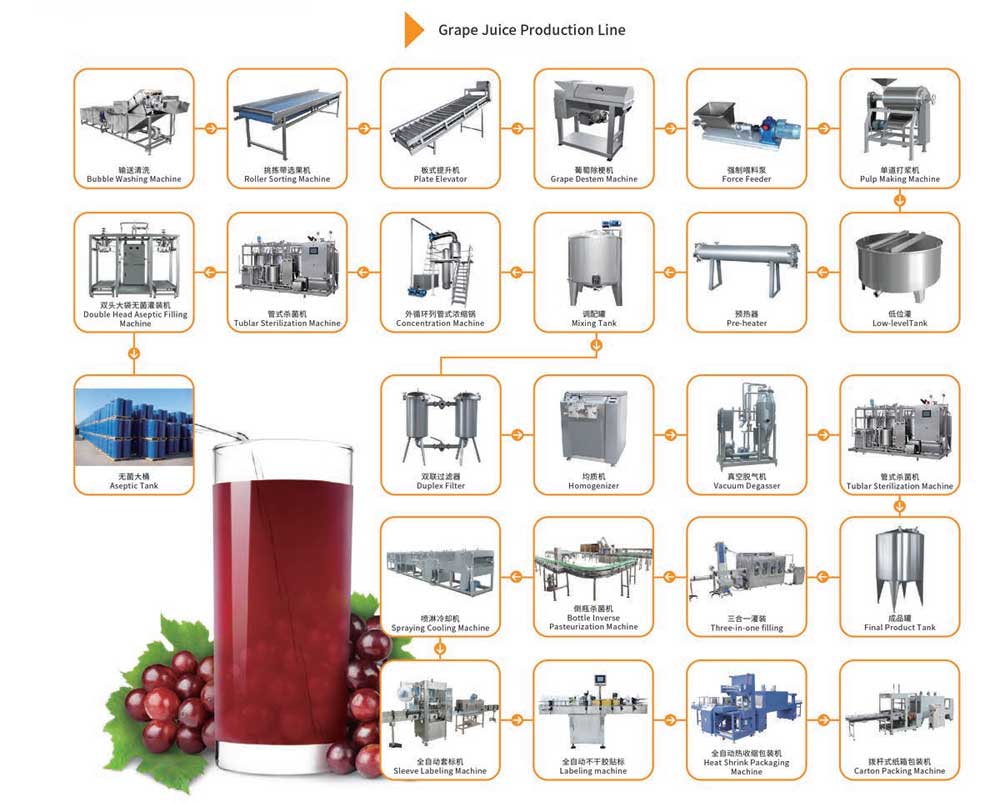

Grape juice production line

Grape juice are extracted from grape pulp. It plays an important role in wine industry, like wine and brandy. But sometimes it is made into drinks without alcohol.

Grape juice production process

Grape juice is popular for its nutritive benefits and good taste. Nowadays, grape juice production has become a promising industry. In grape juice production process, pay attention to the following aspects:

-

Protect the flavor, taste, color and properties of grapes as much as possible

-

Prevent the fade of the pigment, and the precipitation of tartars.

-

The extracted grape juice must be pasteurized to prevent the fermentation of yeasts.

-

Prevent grape juice directly contact with iron, copper and other metals, in case they have chemical reactions.

Grape juice production process includes raw material selection, cleaning, sorting, stem removing, crushing, heating for color distilling, juice extracting, filtration, deploy, clarification, filling and sealing, pasteurization and cooling. The following are Grape juice making machines.

-

Grape vibration separator

-

Fruit surfing cleaning machine

-

Grape destemmer

-

Double-screw grape crusher

-

Plate UHT Sterilizer

-

Metal can filling machine

Raw material selection

The grapes for making juice are required to be fresh and mature, with good flavor. You should get rid of those unripe, overripe and mechanically damaged fruits, or they would contaminate the juice quality. It is better the process the grapes the same day they are picked. If you need to store them, keep the temperature at 0℃ and the moisture of 80%-85%.

To improve the efficiency of selection, experienced producers usually adopts grape vibration separator. It can transmit grapes and separate the unqualified grapes, stems and impurities with high-frequency vibration.

Grape cleaning

After selection, we need to clean the grapes with a fruit cleaning machine. A fruit surfing cleaning machine can scour the grape surface and remove the dirt with tumbling water, without damage to the grapes. To achieve better cleaning effect, you can dip the grapes in potassium permanganate solution for 3min and them rinse them with running water.

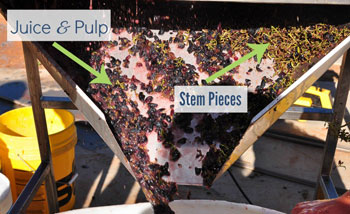

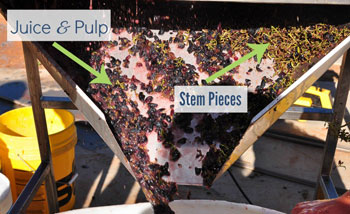

Grape Destemming

Grape stems account for 3-8% the weight of grapes. They are mainly made of lignin, with 1-2.5% tannin, 0.5-1.5% acid and a little bitter compound. They must be removed from grapes in case they contaminate the grape juice.

Grape destemmer is a specialized equipment to remove stems on grapes and protect the integrity of the grape grains. The crushing roller is made of non-toxic and high-elastic rubber, with no damage to the grapes. Then a single-screw pump transmit the grapes to the next process for juice extraction. The pore size of the drum sieve can be customized according to the size of grapes.

Features of grape destemmer

-

It adopts eccentric and adjustable destem blade. The rotating speed can be adjusted to adapt to different grape sizes. It improve the removing rate and the integrity of grains.

-

The sieve is made of nylon, with resistance to acid, alkali and corrosion.

-

For production capacity larger than 5t/h, it is equipped with wheeled separator.

Grape juice extraction

After destemming, the grapes are extracted by a double screw grape crusher. It can crush the grapes into juice and separate skins and residues. The contacting parts with raw materials are made of SUS304 stainless steel. It adopts low squeezing speed to achieve high juice yield. The pressure and humidity are adjustable. Besides, it also applies to fermentative grapes and high-fiber contents.

Grape juice filtration

The crude grape juice contains some slag after extraction. You can filtrate it with fabric cloth sack, and collect the clear juice in stainless steel tanks.

Heating for color distill

This is an additional process for make red grape juice. It aims to dissolve the grape pigment in the grape juice by heating the crushed grapes up to 60-70℃ for 15min.

Grape juice blending

Add 20% sugar liquor to raise the sugar degree of grape juice to 16%. Then add 3kg 2% tartaric acid solution to every 100kg grape juice to prevent tartar precipitation.

Methods to make up 2% metatartaric acid solution: Add 1kg metatartaric acid to every 49kg water. After 2-hour soak and 5min boil, blend to promote dissolution, and filtrate it with flannel. After that, add water to 50kg, and cool it quickly for later use.

Grape juice clarification

Gelatin and tannin are usually used to clarify grape juice. Add 4-6g tannin to every 100kg juice. After 8 hours, add 6-10kg gelatin. Keep the temperature between 8℃ and 12 ℃. When all floccules in the juice settled, suck out the clear liquor with tubs.

Pasteurization and filling

Pasteurization requires high temperature and short time. The grape juice is heated up to 90℃ for 30s. Hot filling and aseptic cold filling are 2 common ways of filling. In hot filling, when the grape juice is cooled to 85℃, it can be filled into cans and sealed. In aseptic cold filing, the grape juice is cooled to room temperature and filled into bottles under aseptic condition.

Nutritive value of grape juice

Grape juice is known as plant milk. It has the following nutritive value:

-

Grape contains 16% carbohydrate (most are glucoses), 0.5% plant fibers, potassium chloride, iron and phosphorus, digestible sugar. These substance contribute to the balance of blood acid, and the building of bones and nerves.

-

Grapes contains the highest iron content of all Summer fruits. They are good for people with anemia.

-

Grape juice can improve our immunity to diseases. As proved by scientists, every 100g grapes contains vitamin A 50 IUs, vitamin C 100 IUs, and vitamin B2 10 IUs.

-

Grape is good for nephritis patients, because it can reduce the albumin and sodium chloride in kidney, as shown by researches.

-

Grape juice can improve liver function and promote choleresis. Some doctors includes grape juice in the recipe of diabetics, because it contains substance like insulin.

-

Grapes contains falconoid and polyphenol that can inhibit the platelet aggregation and prevent heart disease.

AGICO is a professional fruit juice production line manufacturer and supplier. We can provide fruit juice making machines for apple, mango, pineapple, orange, pomegranate, grape, etc. Both complete line and independent machinery is available. Welcome to contact us to get the price or know more details

Get in Touch Now!