Fruit pulp extraction machine

Fruit pulp extraction machine applies to stone fruits like mango, peach, and apricot, berries like kiwi fruit, strawberry, and precooked softened kernel fruits like apple and pear. It can remove stones in fruits, extract pulps, and separate slag.

Features of fruit pulp extraction machine

-

It can separate the fruit pulps and residues automatically.

-

It can work independently or connect with a fruit juice production line.

-

The parts connecting with raw materials are made of superior stainless steels that meet food hygiene standard.

Structure of fruit pulp extraction machine

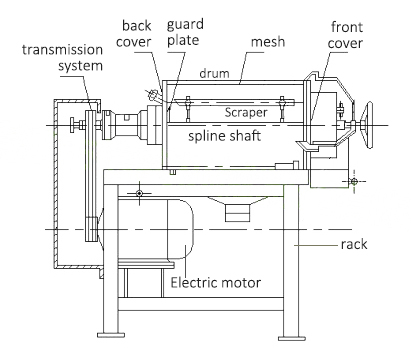

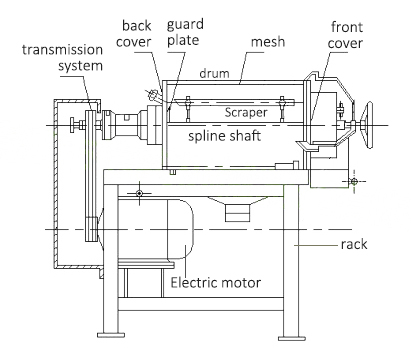

A fruit pulp extraction machine is mainly composed of transmission system, bearing block, sleeve, drum, guard plate, back cover, front cover, spline shaft, screener, scraper or beating bar, rack.

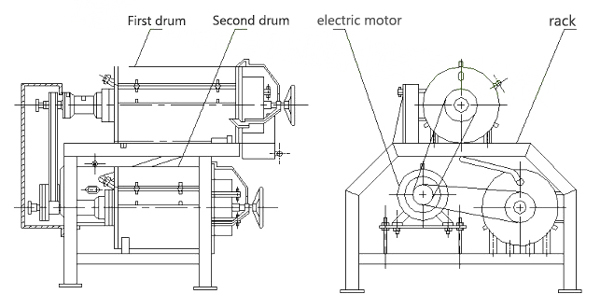

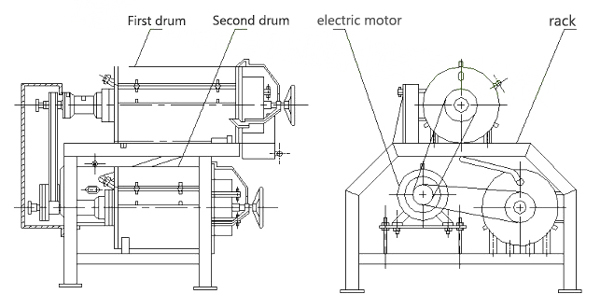

The fruit pulp extraction machine has single-drum and double-drum 2 types.

Double-drum fruit pulper machine is equipped with 2 different rotors in each channel. The first drum is for destoning, the second is for peeling and pulping.

In single-drum fruit pulper machine, you need to replace the rotor of the drum to realize destoning and pulping separately.

For berries and nuts, they only need the pulping drum. If you use a double-drum fruit pulper machine, just install the rotor for pulping in both drums.

Specifications of fruit pulp extraction machine

|

Type |

Raw material |

Capacity |

Rotating speed (RPM) |

Motor Power (KW) |

Demensions |

|

DJ1-2.5 |

mango |

1.5 |

600 |

4 |

1450x770x1650 |

|

tomato |

2.5 |

840 |

|

DJ2-4.0 |

mango |

1.5 |

first-drum |

462 |

7.5 |

1535x1420x1680 |

|

second-drum |

1000 |

|

tomato |

4 |

first-drum |

860 |

|

second-drum |

1000 |

Working principle of fruit pulp extraction machine

Stone fruits pulping process

The electric engine drive the rotor through the V-belt. The fruits get into the machine through the feed hopper. The feeding blade transmit the raw materials to the beating bar that smash the fruits up. Under centrifugal force, the fruit juice and pulp outflow through the screener, while the stones and residues are expelled through the slag hole by the slag blade. In this way, the fruit pulp and slag separate automatically.

Berry fruits pulping process

The electric motor drives the spline shaft through a V-belt. The scrapers on the spline shaft rotate rapidly. When fruits get into the drum through the feed hopper, the guard plate and lead angle push the material toward the exit along the drum in a spiral motion. The raw materials are crushed between the scraper and sieve, with the juice and pulp outflow through the screen mesh, and the peel and seeds discharged through the slag hole. It can realize different pulping speed by adjusting the screener and the lead angle.

Advantages of fruit pulp extraction machine

-

The slag hole is unifomed polished, smooth and clean, and prevent block.

-

The feed port adopt food-grade stainless steel 304, round and smooth, and ensures safe and quick feeding.

-

The electric motor has high capacity, which ensures high extraction speed, and good separating effect. The electric motor is equipped with stainless steel sheild that increase the safety.

-

The scraper and beating bar adopts food-grade material, with fine workmanship.

-

The mesh sizes areΦ0.5, 0.8, 1.0, 1.2, 1.6. We can customize the size according to customer’s need.

How to operate fruit pulp extraction machine?

Before starting the machine:

-

Ensure the connection of rotor parts are tight.

-

The motor rotating direction is in line with the label.

-

Add mechanical oil to the bearings on both ends.

-

Rotate the hand wheel clockwise.

-

Lock the front cover of the drum.

To extract fruit pulp:

-

Feed the raw materials in an uniform speed to the hopper.

-

Adjust the lead angle and the clearance between the scraper and the screener, so that the juice rate meet the requirement.

Stop the machine:

-

Turn the hand wheel counterclockwise.

-

After the motor stops, switch out the main brake.

-

Don’t open the front cover of the drum before the rotor stops completely.

Clean and maintain:

-

Every time after work, clean and lubricate the machine at once, in case the materials are fermented in the drum or the connecting part lose oil.

-

Open the front cover of the drum, screw off the tightening bolt at the end of the spline shaft, and you can take apart the rotor and the screener.

Get in Touch Now!