How beverages are bottled and packed in a factory?

The fruit juice production process includes fruit sorting, cleaning, crushing, heating, juice extraction/pulping, sterilization, filling, and cooling.

After juice extraction and sterilization, the fruit juice is transmitted to the juice bottling plant for bottling and packing. There are 3 methods of bottling: traditional filling, hot filling, and sterile filling.

Traditional filling method

Heat up the fruit and vegetable juice to over 85℃. Filing it into bottles when it is hot, seal the bottles and sterilize at normal temperature, then cool it down.

Tradtitional filling method need long heating time, which affect the fruit juice quality. But it require less on the equipment and technology. It can produce high-quality high-acidity juices.

Hot filling

After processed by High Temperature Short Time (HTST) or Ultra Heat Treat (UHT) sterilization, fill fruit juice into the presterilized bottles or cans and seal them when it is hot. Then turn the bottle upside down quickly, then cool it down.

Hot filling method usually applies to high acidity fruit juice and tea beverages.

Sterile filling

Fruit juice sterilization

The fruit juice are processed by High Temperature Short Time sterilization to preserve the color, taste and nutrition of the products.

Container sterilization

The containers for fruit juice include composite paper container, plastic container, composite plastic film bag, metal can (tinplate, aluminum, and pop-top can), glass bottles.

The sterilization for containers includes thermal sterilization (hot air, superheated steam), radiation sterilization (ultraviolet ray, radial), chemical sterilization (H2O2, ethylene oxide). Sometimes, several sterilization methods are combined together.

Ambient enviroment terilization

Ensure the tightness of joint, valve, heat exchanger, homogenizer, and pump. Keep the positive pressure of the whole system. After the operation finishes, use CIP (Clean In Place) system and add 0.5-2% hot sodium hydroxide solution for circulation scouring. Use Dilute hydrochloric acid to netrualize and hot steam to sterilize. The asepsis room need to be processed by high-efficency air filter so as to meet the hygienic standard.

Juice filling machine

Juice filling usually adopts constant volume method. It can be classified into equal-pressure method and differential-pressure method.

Equal-pressure method refers to the pressure at the top of the fluid reservoir is the same as that in the package container, where the fruit juice flow into the packages by its own gravity. Between the fluid reservoir and the packing containers are 2 channels, one for filling fuid, the other for air discharge. Equal-pressure method is suitable for drinks with low viscosity.

Differential-pressure method means that the pressure in the fluid reservoir is higher than that in the contianer. The filling speed is high, suitable for drinks with high viscosity. Usually they use a air compressor to highten the pressure in the fulid reservoir, or a vacuum pump to to lower the pressure of package container.

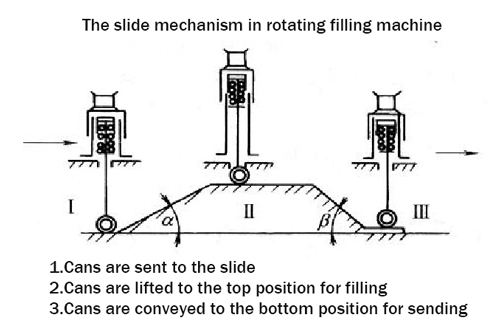

Lifting and conveying mechanism

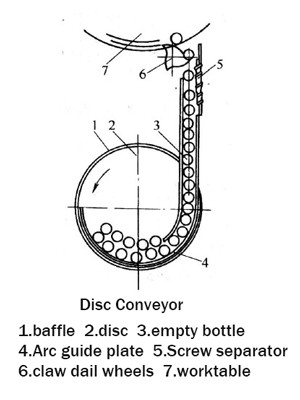

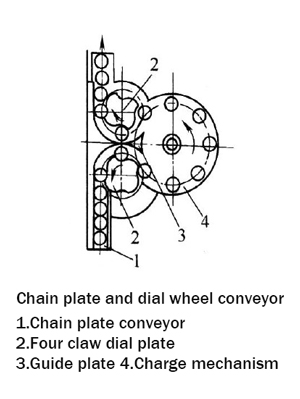

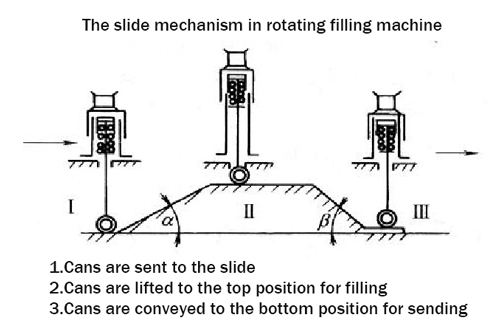

The empty bottles or cans need to be conveyed to the lifting mechanism of the juice filling machine. Usually, they adopt claw dail wheels or spiral conveyors to convey the bottles automatically, continuously, and precisely to the filling machine with the same space between.

The following pictures are respectively disc conveyor, chain plate and dial wheels, and slide type lifting mechanism for bottles and cans.

Filling valve mechanism

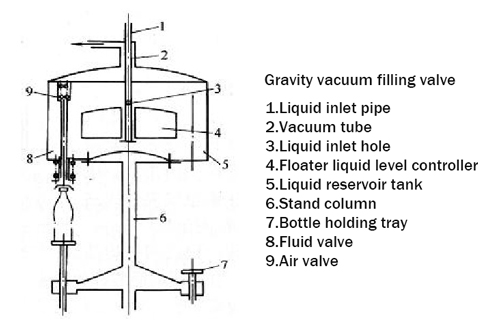

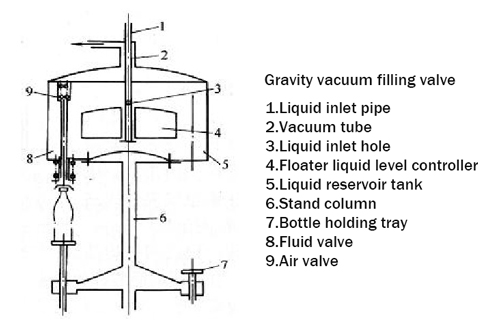

Filling valve is the core part of the juice filling machine. It serves to fill certain quantity of fluid to the bottles and cans from the reservoir. The quality of fill valve directly affect the performance of filling machine. Usually, there are 2 types: gravity type vacuum filling valve, and differential-pressure multi-chamber vacuum filling valve.

Gravity vacuum filling valve

During the filling process, the vacuum pump maintain the vacuum degree at the top of the fluid reservoir, and the floater controller maintain the liquid level in the reservoir stable. When the bottles and cans are conveyed to the designated place, the filling value pumped out the air and keep the pressure in the bottle the same as that in the reservoir. Under this condition, the fluid fill into the bottles under gravity force. This type of filling valve is suitable for uncarbonated drinks.

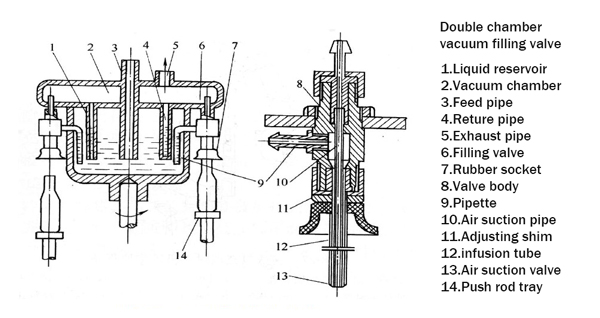

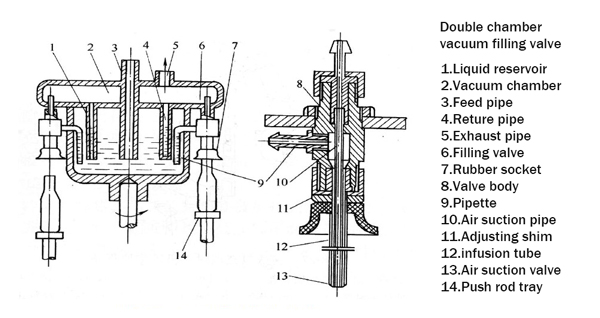

Differential-pressure multi-chamber vacuum filling valve

During the filling process, the fluid reservoir is under normal pressure. When the packages have some vacuum degree, the fluid is sucked in. The filing volume is controlled by the depth that the infusion tube inserts in the bottles.

This type of filling valve is suitable for fluid with high viscosity, such as pulp juice and syrup. The bottles must be sealed right after filling, or the fruit juice may be contaminated for another time.

Fruit juice package materials

The suitable materials for making fruit juice packages should have the following properties.

-

Chemical stability, without chemical reaction to the fluid.

-

No harm to the human body.

-

Good protective effect.

-

Easy to process and mold.

-

Abundant resources and low cost that meet the industrial production demand.

-

Pleasant appearance.

-

Light weight, easy to carry.

Get in Touch Now!