How to make fruit juice concentrate?

Introduction

Fruit juice concentrate plays an important role in making different juice products. As an essential raw material, it have huge impact on juice quality. This passage introduced the most common ways to make fruit juice concentrate, including vacuum concentrate, freeze concentration, membrane concentration and aroma recovery. By comparing these fruit juice concentrate process technology, we can figure out their advantages and weakness, so as to apply them better in juice processing.

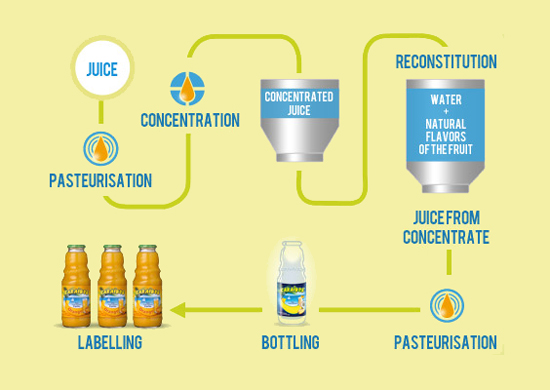

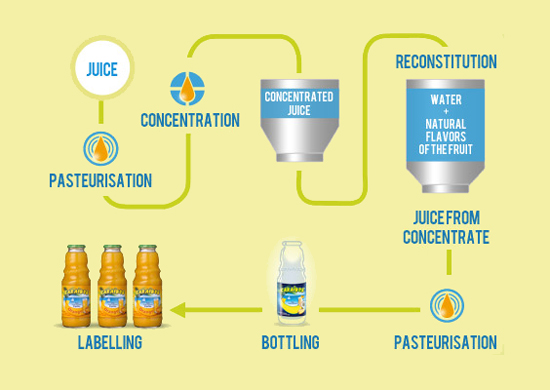

What is fruit juice concentrate

Fruit juice concentrate is made by removing water from freshly squeezed fruit and vegetable juice. It is usually used as base stock for various food products. With less volume, it contains soluble solids of 65%-70%. Fruit juice concentrate process is a effective way to reduce packing and transportation cost. And it guarantee the consistent quality of end products. Meanwhile, with the increase of sugar and acid content, it is in favor of preservation.

To choose suitable concentration technology, quality must come first. Qualified fruit juice concentrate must retain similar color, flavor and nutrition as original fruit juice after diluted. In this regard, the concentration process must be carried out under low temperature. The most popular fruit juice process technology are vacuum concentrate method, concentration by refrigeration, membrane technology concentration. Besides, in fruit juice concentration process, aroma recovery is an influential step we can’t ignore.

Vacuum concentrate method

Vacuum concentration requires heating fruit juice under low pressure so as to reduce the boiling point and let the water content evaporate rapidly. Vacuum concentration equipment is the most important and widely adopted device in fruit juice concentrate process. It can be classified into single-effect and multiple-effect concentrate device. Based on the heater structure, it includes central circulation tube evaporator, coil evaporator, rising film evaporator, falling film evaporator, plate type evaporator, scraper evaporator and centrifugal film evaporator.

Take vacuum film concentrator for example. The temperature is lower than 30-40e, sometimes even as low as 22-25e. As for heat pump concentration system, it uses the heat generated by refrigerator as heat source, and inflated refrigerants as cooling agency, representing higher heat utilization. Under the condition of high vacuum degree, the concentration temperature is lowered to 15-20e, which can protect the quality of concentrated juice.

The heat required by evaporation and concentration comes from primary steam and secondary steam. The former one is called single-effect evaporation, during which the secondary steam is condensed directly rather than used for heating. If the secondary steam is used for another heating, this process is called multiple-effect evaporation. Generally, fruit juice concentrate goes through 1-5 times evaporation, with the solid content raised up to 70%-72% from 5%-15%.

Characteristics of vacuum concentrate

As fruit juice concentrate is conducive to storage and transportation, it is in growing demand in juice processing industry. Vacuum concentrate method can shorten the process time and preserve the fruit juice quality at the same time, compared with high temperature and normal temperature concentration. The general temperature for vacuum concentration is 35℃, the vacuum degree is 94.7Kpa. To prevent microbe production and enzyme activity under this favorable condition, we need pasteurize it ahead of time.

Freeze concentration

Freeze concentration means lower the temperature of fruit juice to ice point. Before fruit juice concentration reaches up to eutectic point, the water contents get frozen and separated. As we all know, concentration of a solution is restricted to a certain range. When solute contents exceed eutectic concentration, they are separate out in the term of crystal from the supersaturated solution.

On the other hand, if solute content is lower than eutectic concentration, the water content is separated out in the term of ice crystal. With the separation of solvent, the proportion of solute gets much higher. The above are basic principle of freeze concentration.

Characteristics of freeze concentration

This method is especially suitable for thermally sensitive food. It can avoid volatilization of aromatic compounds caused by heating. In terms of food with volatile substance, freeze concentration is superior than vacuum concentration and membrane concentrate.

However, freeze concentration has the following disadvantages. First, the processed food have to go through cold or heat treatment for preservation. Second, freeze concentrate effect is not only determined by solution concentration, but the separation degree between crystal and concentrated solution. Generally speaking, if a solution has high viscosity, it is hard to separate solute from solvent. Third, content loss is inevitable in freeze concentration, and the process cost is rather high.

Membrane concentrate

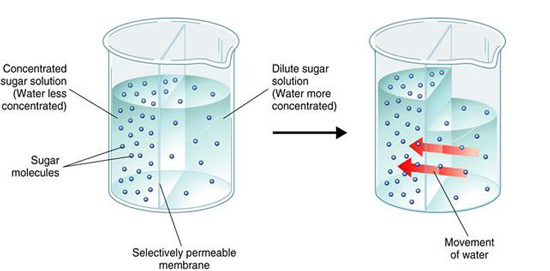

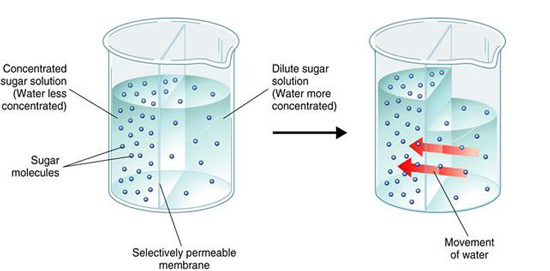

Membrane technology includes reverse osmosis and ultrafiltration. It adopts osmotic pressure as principle. A container is divided into 2 parts by a semipermeable membrane installed in the center, with each part separately filled with solution A and solution B.

As solution B infiltrate part A through the membrane, there forms a osmotic pressure from the B part. Specifically, osmotic pressure is inversely proportional to the concentration disparity between 2 parts. That is to say, if the concentration in part A is larger than part B, then water infiltrate A from B. By contrast, if there is a larger pressure put on part A, then water will permeate from A to B, which is called reverse osmosis.

Reverse osmosis and ultrafiltration are similar in principle, while the former one requires higher operation pressure, with no small particles passing through. Reverse osmosis effect is determined by semipermeable membrane property and water infiltration speed.

Characteristics of Membrane concentrate

Revers osmosis have the following advantages:

-

The concentration process is carried out under low temperature, effectively avoiding qualitative change.

-

The nutrients and flavor substance remain in fruit juice concentrate are kept in high rate.

-

Membrane technology is more energy-efficient than other methods.

-

Currently, membrane technology functions as preconcentration process, for it is unable to achieve higher concentration degree.

Aroma recovery

Fresh fruit juice contains various aromatic substance, also called essence, including Esters, alcohols, hydroxyl compounds and other kinds of organic matters. They are distributed in certain proportion and constitute flavor of various fruits.

Fruit juice concentrate may lose aromatic substance during evaporation process, which makes aroma recovery essential. There are 2 ways to retrieve aromatic substance. The first one is to extract and separate aromatic matters and add them to concentrate fruit juice. The other one is to separate and recover steams in concentration tank, and then add them to end products.

Prospect of fruit juice concentrate

Concentrated fruit juice are directly extracted from natural fruits and vegetables, with the advantages of high nutritive value and no pollution. It can not only be diluted for drinking, but serves as a base stock in food processing industry. Wide application and strong market potential makes it a popular investment spot.

Fruit juice concentrate process technology, as the essential step in fruit juice production, has huge impact on juice quality. In this regard, choosing the proper fruit juice concentrate technology is the key to improve juice productivity and quality.

Get in Touch Now!