Potato Washing and Peeling Machine

Potato Washing and Peeling Machine Introduction

In the modern vegetable and fruit deep-processing industry, a high-efficiency and low-loss potato washing and peeling machine has gradually become an indispensable core device for food factories, central kitchens, and agricultural product distribution centers.

Potato washing and peeling machine integrates potato washing, mud removal, and surface peeling into an automated workflow, it makes the potato processing line more efficient, hygienic and stable. Especially for the potato chips production line, potato washing peeling machine is the most reliable pre treatment machine. It can keep the integrity of the potatoes and in the same time potato washer and peeler machine can wash potatoes clean.

Send Inquiry Now!

Before entering the production line, potatoes usually carry mud, sand, stones, and surface impurities. Using separate washing machines or manual cleaning is not only inefficient but also difficult to standardize. The potato washing peeling machine combines brush rollers, spraying systems, and abrasive peeling mechanisms to complete washing, tumbling, and friction-type peeling in one step. This significantly reduces labor involvement and has become the commonly used pretreatment equipment in small and medium-sized processing plants as well as in a potato chips production line.

Potato washing and peeling machine is also widely known as a potato washer and peeler machine, featuring simple structure, intuitive operation, easy maintenance, and a wide range of processing capacities.

AGICO Main Types of Potato Washing Peeling Machine

AGICO mainly provides three types of potato washing and peeling machine: the brush roller type or called brush washing peeling machine, the screw type peeling machine and the emery drum abrasive washing peeling machine. All AGICO potato washing peeling machines can wash and peel potatoes simultaneously, preparing them for the next stages of processing. Our potato washing peeling machine has a high peeling rate of up to more than 98%. The capacity ranges from 200kg/h to 3000kg/h to suitable for potato chips production of any scale. Besides potatoes, our washer and peeler machine can process some other round fruits and vegetables, like sweet potatoes, carrots, ginger, lotus roots, beets, taro, etc.

Brush type potato washing peeling machine

Screw type potato washer and peeler machine

Drum type potato washing and peeling machine

Brush Type Potato Washing and Peeling Machine

Main Components of Brush Roller Washing and Peeling Machine

The brush roller washing and peeling machine is mainly composed of the following parts:

-

Soft/Hard Brush Rollers: Usually 7–13 rollers. Depending on the material and processing purpose, users can choose soft brushes, hard brushes, or a combination of both.

-

Stainless Steel Body.

-

Spray Pipe System.

-

Motor & Gearbox.

-

Waste Collection Tray and Drain Outlet.

-

Discharge Port (manual discharge or automatic tilting discharge).

Brush type potato washer and peeler machine

Brush type potato washer and peeler machine working

Send Inquiry Now!

Working Principle of Brush Washer and Peeler Machine

During operation of the brush washer and peeler machine, potatoes continuously tumble on the rotating brush rollers. With the combined action of brushes with different hardness levels and the water spray system, the machine can achieve: effective removal of mud, sand, and surface impurities, light peeling and cleaning of sprout marks and attached soil.

The cleaning and peeling process is gentle and does not damage the shape of the potatoes. However, the peeling strength is not as strong as the screw type abrasive peeling machine or the emery drum washing peeling machine.

Application Scope

Brush type potato washing and peeling machine is suitable for: potatoes, sweet potatoes, carrots, ginger, lotus root, beetroot, taro, and other root vegetables.

Functions: washing, light peeling, and surface treatment.

Outlet of brush potato washer and peeler machine

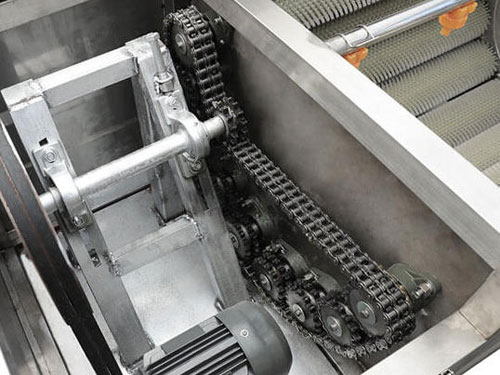

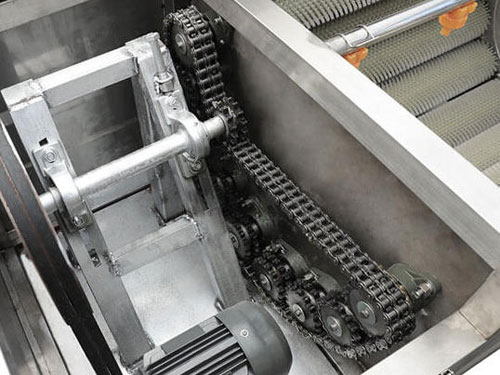

Transmission of brush potato washer and peeler machine

Movable wheel of brush potato washer and peeler machine

Spraying nozzle and water inlet

Brush roller of washer and peeler machine

Send Inquiry Now!

Advantages of Brush Type Potato Waher and Peeler Machine

-

Integrated washing and peeling.

-

Gentle processing, ideal for products that require intact appearance.

-

Simple structure with low maintenance cost.

-

Wide capacity range, available from 200 kg/h to 5000 kg/h.

-

Replaceable brush rollers to adapt to different types of vegetables.

Emery Drum Abrasive Washing Peeling Machine

Working Principle of Emery Drum Washing Peeling Machine

After potatoes or other root vegetables are fed into the peeling chamber, they are continuously rubbed against the high-speed rotating emery-coated plate or drum, which rapidly removes the outer skin.

Water is simultaneously sprayed into the chamber to wash away peel residues, reduce friction heat, maintain a smooth product surface, and achieve extremely fast peeling.

Under normal conditions, a batch can be finished within 20–40 seconds.

Our abrasive washing peeling machine, or called emery drum washing peeling machine, uses an emery-coated drum to achieve strong, efficient, and uniform peeling performance.

Structure of Abrasive Washing Peeling Machine

The abrasive washing peeling machine, also known as an emery drum washing peeling machine, is mainly composed of:

-

Abrasive Plate / Drum.

-

High-Speed Rotating Shaft.

-

Agitator / Turning Plate.

-

Stainless Steel Shell.

-

Automatic Water Feeding & Spraying System.

-

Automatic Discharge Gate.

Send Inquiry Now!

Emery type potato washer peeler machine structure

Application of Emery Drum Washing Peeling Machine

This machine is widely used in:

Large-scale industrial processing lines.

Frozen french fries plants.

Potato chips factories.

Dehydrated vegetable production lines.

Suitable for peeling potatoes, sweet potatoes, taro, jicama (yam bean) and other root vegetables that require complete and fast peeling.

Advantages of Emery Drum Washing Peeling Machine

-

Extremely high peeling efficiency (up to 95%–98%).

-

Very fast peeling speed, ideal for intense, continuous production.

-

Uniform peeling with smooth, clean surface.

-

Easy integration into automatic processing lines with elevator, sorting machine, cutting machine etc.

Parameter of Emery Potato Washing and Peeling Machine

|

Model |

Power |

Dimension |

Weight |

Capacity |

|

AG-10 |

0.75kw/220v |

690x410x800mm |

60kg |

150kg/h |

|

AG-30 |

1.1kw/380v |

740x650x860mm |

80kg |

300kg/h |

|

AG-80 |

1.5kw/380v |

880x960x1000mm |

130kg |

500kg/h |

Screw Type Washing and Peeling Machine

The screw type washing and peeling machine is a modern, widely used equipment for cleaning and peeling root vegetables and fruits. Its core structure is a long tank equipped with a screw conveyor, which moves the materials forward continuously. During the forward movement, materials are rubbed and tumbled by brush rollers, abrasive plates, and high-pressure water spraying, achieving both washing and light peeling.

It is suitable for processing: potatoes, sweet potatoes, carrots, white radish, ginger, water chestnut, taro, beet, apples, pears, and similar products.

Screw type potato washing peeling machine details

Screw type potato washing peeling machine details

Send Inquiry Now!

Working Principle of the Screw Type Washing Peeling Machine

Raw materials enter the tank through the feeding inlet. The rotating screw blades push the materials forward continuously. During movement, materials rub against the brushes or abrasive plates. High-pressure water sprays remove mud, sand, and peel residues. Clean and partially peeled materials are discharged automatically from the outlet.

This continuous-flow processing method is especially suitable for: high-capacity factories, fully automated production lines, processing lines that need to connect sorting, cutting, blanching, and further processing equipment

Screw potato washing peeling machine

Screw potato washing peeling machine working

Advantages of Screw Type Washer and Peeler Machine

-

High Automation Level

Easily connects with lifting conveyors, sorting machines, blanching machines, frying equipment, etc. forming a fully automated production line.

Screw Type Potato Washer and Peeler Machine Specification

|

Model |

Power(KW) |

Size(mm) |

Capacity(KG/H) |

Weight(KG) |

Roller Size(mm) |

|

AGXM800 |

1.1 |

1600*850*800 |

400 |

220 |

800 |

|

AGXM1000 |

1.5 |

1800*850*800 |

600 |

260 |

1000 |

|

AGXM1200 |

1.5 |

2000*850*800 |

800 |

280 |

1200 |

|

AGXM1500 |

2.2 |

2300*850*800 |

1000 |

320 |

1500 |

|

AGXM2000 |

3 |

2800*850*800 |

1500 |

420 |

2000 |

|

AGXM2600 |

4.37 |

3100*850*1450 |

2000 |

600 |

2600 |

Get in Touch Now!

Brush type potato washing peeling machine

Brush type potato washing peeling machine Screw type potato washer and peeler machine

Screw type potato washer and peeler machine Drum type potato washing and peeling machine

Drum type potato washing and peeling machine Brush type potato washer and peeler machine

Brush type potato washer and peeler machine Brush type potato washer and peeler machine working

Brush type potato washer and peeler machine working Outlet of brush potato washer and peeler machine

Outlet of brush potato washer and peeler machine Transmission of brush potato washer and peeler machine

Transmission of brush potato washer and peeler machine Movable wheel of brush potato washer and peeler machine

Movable wheel of brush potato washer and peeler machine Spraying nozzle and water inlet

Spraying nozzle and water inlet Brush roller of washer and peeler machine

Brush roller of washer and peeler machine Emery type potato washer peeler machine structure

Emery type potato washer peeler machine structure Screw type potato washing peeling machine details

Screw type potato washing peeling machine details Screw potato washing peeling machine

Screw potato washing peeling machine

Screw potato washing peeling machine working

Screw potato washing peeling machine working