Impingement Tunnel Freezer

Impingement Tunnel Freezer | High Velocity Air Freezing System

An impingement tunnel freezer is a mechanical freezing system designed for high-capacity, continuous food processing lines. It uses controlled, high-velocity cold air directed onto the product surface to achieve fast and consistent freezing.

Compared with conventional air blast tunnel freezers, the impingement design improves heat transfer efficiency and reduces freezing time, making it suitable for processors who require stable output, uniform product quality, and predictable operating costs.

This type of tunnel freezer is widely used in large-scale industrial environments where long operating hours and consistent performance are critical.

Impingement tunnel freezer for high speed and continuous food processing

Impingement tunnel freezer for high speed and continuous food processing

Request a Freezing Solution

What Is Impingement Freezing Technology?

Impingement freezing is based on the principle of direct air jet impact.

Unlike traditional air circulation freezing, impingement systems use:

-

Precisely designed air nozzles.

-

Extremely high air velocities.

-

Uniform airflow distribution above and below the product.

These high-speed air jets break the thermal boundary layer on the food surface, dramatically increasing heat transfer rates and reducing freezing time.

How Does an Impingement Tunnel Freezer Work?

In an impingement tunnel freezer, cold air is accelerated through specially designed nozzles and delivered directly onto the upper and lower surfaces of the product as it moves through the tunnel on a conveyor belt.

The high-speed airflow breaks the insulating air layer on the product surface, allowing heat to be removed more efficiently than with traditional circulating air systems. Multiple freezing zones can be configured along the tunnel to control temperature, airflow intensity, and residence time, ensuring consistent freezing results for different product types.

From the outside, an impingement tunnel freezer looks similar to other mechanical tunnel freezers. The key difference lies in the internal airflow system, where high-velocity air is directed onto the product surface through specially designed nozzles.

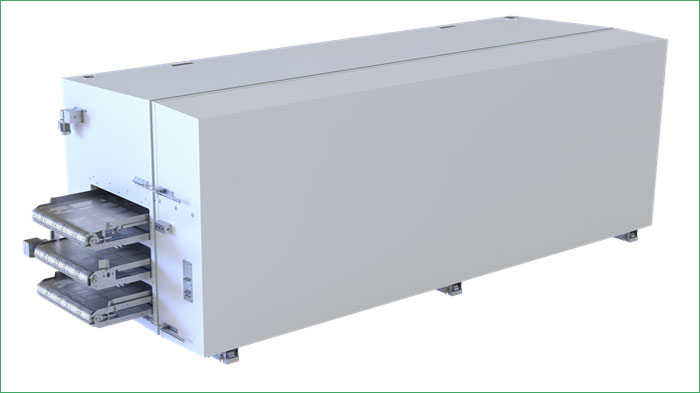

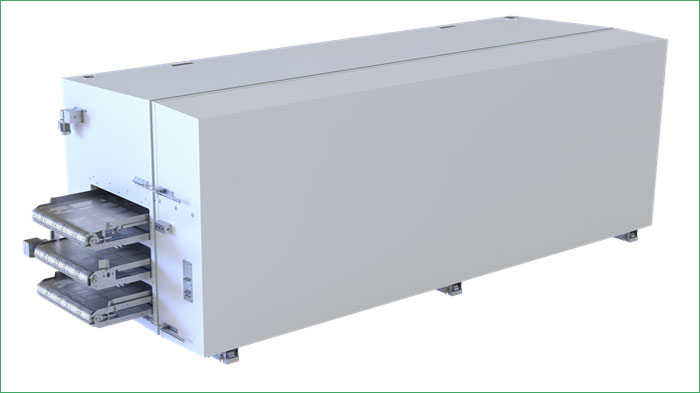

3 layers impingement tunnel freezer

Single layers impingement freezer

Request Technical Details

Key Features of Impingement Tunnel Freezer

Extremely fast freezing compared with conventional air blast freezers

Impingement tunnel freezers use high-velocity, directionally controlled air jets that directly impact the product surface. Compared with traditional air blast tunnel freezers, this design significantly increases heat transfer efficiency, allowing products to freeze faster while maintaining consistent freezing conditions throughout the tunnel.

Uniform freezing on both upper and lower product surfaces

The impingement airflow system is arranged above and below the conveyor belt, ensuring that cold air reaches all exposed product surfaces simultaneously. This balanced airflow minimizes temperature gradients, reduces uneven freezing, and helps achieve consistent core temperatures across each product.

Precise temperature and airflow control

The system allows independent control of air velocity, airflow direction, and freezing temperature across different tunnel zones. This level of control enables processors to fine-tune freezing parameters for different product types, thicknesses, and loading patterns, ensuring stable and repeatable freezing results.

High production capacity for continuous operation

Impingement tunnel freezers are designed for high-throughput, continuous production environments. Their efficient heat exchange and stable airflow system support large processing volumes, making them suitable for industrial-scale food processing facilities operating multiple shifts.

Impingement freezer working

Impingement freezer working

Send Your Product Details

Energy-efficient mechanical refrigeration system

Despite high airflow velocities, impingement tunnel freezers rely on optimized mechanical refrigeration and recirculated cold air. Compared with less controlled air blast systems, this results in improved energy utilization and lower energy consumption per unit of product over long-term operation.

Robust structure suitable for industrial environments

The tunnel frame, enclosure, and internal components are built to withstand continuous operation under low-temperature conditions. Industrial-grade materials and reinforced structural design ensure long service life and stable performance even in demanding production environments.

Easy cleaning and hygienic design for food safety compliance

The freezer is designed with food safety requirements in mind, featuring smooth internal surfaces, accessible airflow components, and drainage-friendly layouts. These features simplify cleaning procedures, reduce contamination risks, and help processors comply with international food hygiene standards.

Advantages Compared with Conventional Air Blast Tunnel Freezer

Compared to standard air blast tunnel freezers, impingement tunnel freezers offer:

-

Higher heat transfer coefficients.

-

Shorter freezing times.

-

Reduced freezer length for the same capacity.

-

More consistent product core temperature.

-

Improved product appearance and texture.

This makes impingement technology a preferred solution for processors aiming to increase output without expanding factory footprint.

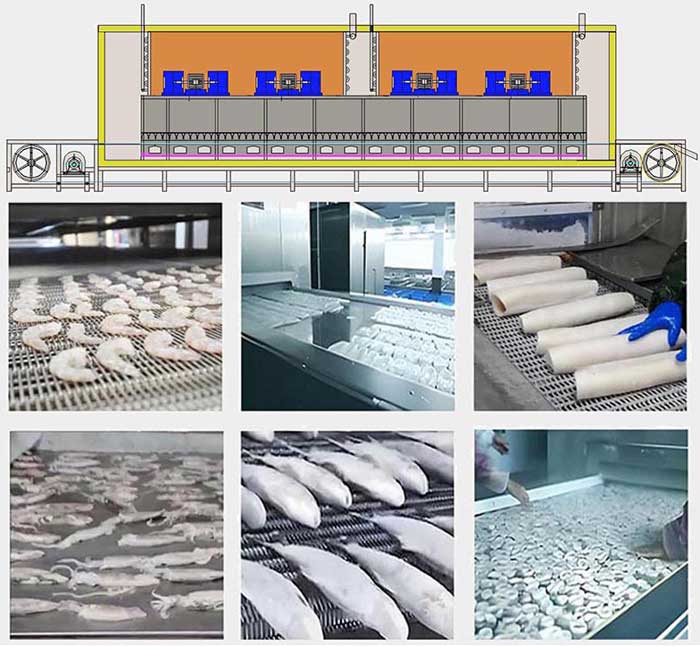

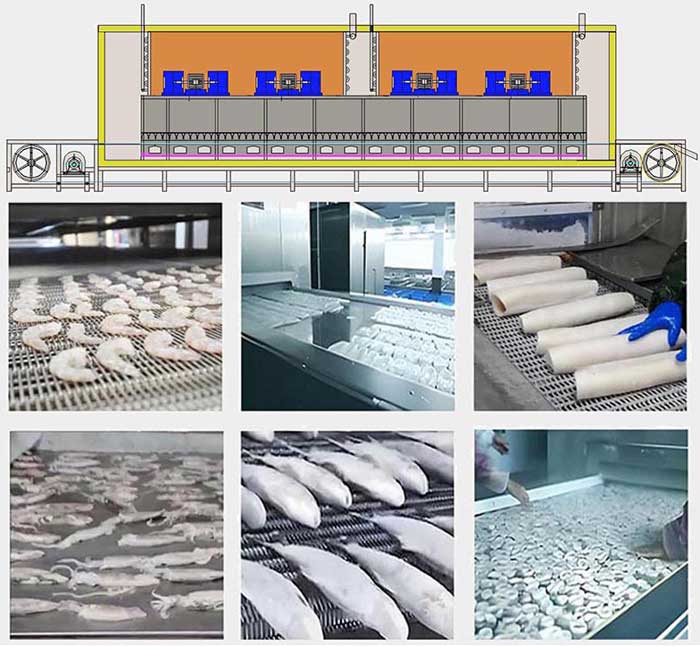

Applications of Impingement Freezer

Impingement tunnel freezers are commonly used for freezing products such as meat and poultry products like beef burgers and patties, chicken nuggets, breaded and battered meat products etc., seafood such as fish portions and fillets, bakery items like pizza bases, flatbread and dough sheets etc, prepared foods, and other products requiring fast and uniform freezing like frozen snacks, coated or pre-fried products etc.

They are especially suitable for applications where high throughput, consistent freezing quality, and long-term operating efficiency are important considerations.

Bakery

Seafood

Meat

Ready meals

Request a Customized Solution

Impingement Tunnel Freezer vs Liquid Nitrogen Tunnel Freezer

While both systems offer fast freezing performance, they are designed for different production needs:

Impingement Tunnel Freezer

-

Mechanical refrigeration system.

-

Lower long-term operating cost.

-

Ideal for large-scale continuous production.

Liquid Nitrogen Tunnel Freezer

-

Cryogenic freezing using liquid nitrogen.

-

Extremely fast freezing speed.

-

Higher operating cost due to nitrogen consumption.

-

Best for high-value or specialty products.

Impingement tunnel freezers are often selected when stable production volume and cost control are critical.

Why Choose Our Impingement Tunnel Freezer?

-

Experienced manufacturer of industrial food freezing equipment.

-

Advanced impingement airflow design.

-

Durable stainless steel construction.

-

Stable performance with low maintenance needs.

-

Complete technical support and solution planning.

We focus on delivering reliable, high-efficiency freezing solutions for food processing industries worldwide.

Our advantages

Our advantages

Customization Options

Each impingement tunnel freezer is engineered based on specific processing requirements rather than supplied as a standard model.

Customization options include adjustments based on product size and thickness, required freezing capacity, conveyor belt width and length, refrigeration system configuration, and available factory space. The tunnel layout can be designed to integrate smoothly with upstream and downstream equipment in existing production lines.

Typical Technical Parameters

The following parameters are provided as general reference ranges. Final specifications are determined according to actual production conditions.

-

Freezing capacity: configured according to throughput requirements.

-

Inlet product temperature: chilled or ambient, depending on upstream process.

-

Outlet product temperature: designed to meet frozen storage requirements.

-

Tunnel length: customized based on freezing time and line speed.

-

Conveyor belt width: multiple standard and customized options.

-

Conveyor speed: adjustable for precise residence time control.

-

Refrigeration system: industrial mechanical refrigeration.

-

Construction materials: stainless steel food-contact surfaces.

-

Control system: centralized control with real-time monitoring.

Request Technical Details or Quotation

If you are searching for a professional impingement tunnel freezer manufacturer, please contact us with your product information and required capacity.

Our engineers will provide a customized freezing solution based on your production needs.

Get in Touch Now!

Impingement tunnel freezer for high speed and continuous food processing

Impingement tunnel freezer for high speed and continuous food processing 3 layers impingement tunnel freezer

3 layers impingement tunnel freezer Single layers impingement freezer

Single layers impingement freezer Impingement freezer working

Impingement freezer working Bakery

Bakery Seafood

Seafood Meat

Meat Ready meals

Ready meals Our advantages

Our advantages