Corn Freezer

Corn Freezing Solutions for IQF Corn Kernels and Whole Corn Cobs

As we all know, sweet corn is a common food in our daily lives. But corn is a high-moisture agricultural product, and improper freezing may cause problems such as clumping, texture damage, or incomplete freezing.

In this situation and with the rapid growth of the frozen food industry, frozen corn products have become increasingly popular in global markets. IQF sweet corn is one of the methods that can preserve the corn for a long time.

Send Inquiry Now!

However, different corn products like corn kernels or whole corn cobs require completely different freezing technologies. When freezing corn, there are two different and widely used corn freezers based on the corn form and processing requiremnents, one is a fluidized bed freezer or iqf freezer for corn kernels, and the other is the whole corn tunnel freezing machine. Customers can choose the most suitable and right freezing solution according to different corn forms and different corn freezer structures.

At our company, we provide professional corn freezing solutions for both IQF corn kernels and whole corn cobs, helping food processors achieve high product quality, stable production, and efficient energy use. Each corn freezing solution uses a different freezing principle, equipment structure, and process design, ensuring optimal freezing results for each product type.

Our certifications

IQF Corn Kernel Freezing Machine

Fluidized Bed Freezer Introduction

The IQF corn kernel freezing machine mainly refers to fluidized bed freezer, is specially designed for fast and uniform freezing of corn kernels.

By using fluidized bed freezing technology, each corn kernel is frozen individually, preventing clumping and preserving natural color, taste, and nutrition. This solution is widely used in export-oriented frozen vegetable processing plants coordinating with pr-treatment equipment such as corn sheller, blanching machine, cooling and dewatering system etc.

Send Inquiry Now!

Freezing Principle of Fluidized Bed Freezer

The fluidized bed freezer places the raw materials to be frozen on a fine-mesh conveyor belt or a perforated tray with a low open area ratio.

High-speed cold air flows vertically upward, causing food particles to enter a semi-fluidized state (semi-fluidized freezing) or a fully fluidized state (full fluidized freezing).

In this state, the suspended product particles are completely surrounded by low-temperature air and are rapidly frozen.

Through the combined effect of mechanical vibration and air pressure, the product floats and moves smoothly on the stainless steel mesh belt, achieving individually quick freezing and effectively preventing product clumping or sticking.

Structurally, the fluidized bed freezer is available in single-stage, double-stage, and four-linkage fluidized bed designs, allowing equipment selection based on different product characteristics. Freezing capacity can be customized according to production requirements. Stainless steel fans ensure rated air volume and air pressure.

A large aluminum alloy evaporator with an expanded air-facing surface and variable fin pitch design extends frosting intervals and improves heat exchange efficiency.

The feeding section is equipped with mesh belt cleaning and air-drying devices.

A fully automatic control system combined with frequency conversion technology allows stepless adjustment of conveyor belt speed.

All internal components are made of stainless steel, ensuring easy cleaning, maintenance, and compliance with food hygiene standards.

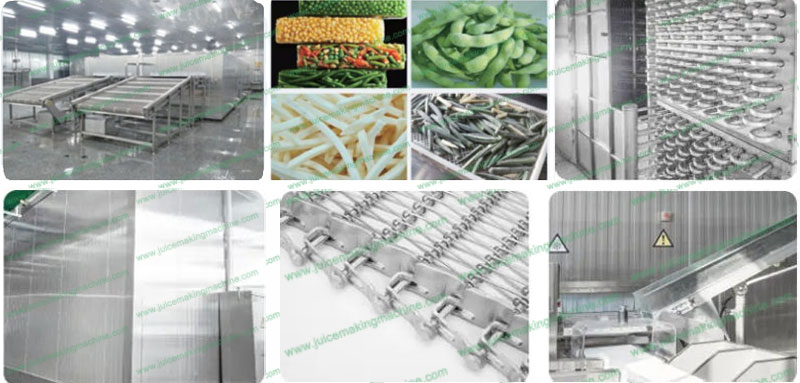

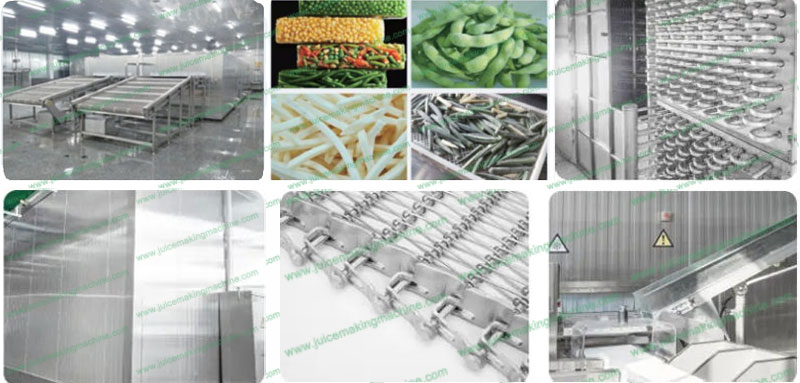

Corn freezer applications

Send Inquiry Now!

Advantages of IQF Corn Kernel Freezing Machine

-

Individually frozen kernels without sticking.

-

Extremely fast freezing speed.

-

Uniform product size and appearance.

-

Excellent rehydration performance.

-

Meets international IQF frozen food standards.

Applications of Fluidized Bed Freezer

The fluidized bed freezer is an ideal solution for rapid freezing of granular, sliced, strip-shaped, or diced fruit and vegetable products, such as strawberries, French fries, green beans, red kidney beans, peas, chili peppers, cucumber slices, corn kernels, garlic cloves, carrots, bamboo shoots, cauliflower, mushrooms, and more.

Whole Corn Tunnel Freezing Machine

Tunnel Freezing Machine Introduction

The whole corn tunnel freezing machine or called whole corn tunnel freezer is designed for freezing entire corn cobs, husked corn cobs or pre-blanched corn on the cob, which require deep and uniform freezing due to their larger size and higher density.

This solution focuses on penetrating freezing, ensuring that the corn is completely frozen from surface to core.

AGICO tunnel freezer in the factory

Final tunnel freezer for sale

Send Inquiry Now!

Freezing Principle of Tunnel Freezing Machine

Whole corn cobs are conveyed through a low-temperature tunnel. Cold air circulates evenly around the product, allowing gradual and stable freezing until the core temperature reaches the required level.

Tunnel Freezing Machine Advantages

-

Suitable for large-size agricultural products.

-

Uniform freezing without internal thawing.

-

Continuous and stable operation.

-

Simple structure and easy maintenance.

-

Ideal for long-term industrial production.

IQF tunnel corn freezer

Send Inquiry Now!

How to choose IQF Corn Kernels and Whole Corn Cobs?

Choosing the right freezing technology based on your product form is essential for achieving the best freezing results and reducing operating costs. So when you want to freeze corn, please ensure you want to freeze corn kernels or whole corn cob, then to choose the most suitable corn freezer.

Comparason between IQF Corn Kernels and Whole Corn Cobs

|

Item |

IQF Corn Kernels |

Whole Corn Cobs |

|

Product form |

Individual kernels |

Whole corn |

|

Freezing requirement |

Non-clumping, ultra-fast |

Deep and uniform |

|

Freezing principle |

Fluidized bed IQF |

Penetrating tunnel freezing |

|

Recommended equipment |

Fluidized Bed Freezer |

Tunnel / Spiral Freezer |

|

Application market |

Export frozen vegetables |

Retail & food service |

Contact Us for Customized Corn Freezing Solutions

In addition to freezing machines, we can provide complete corn freezing line solutions, including: corn shelling and preparation equipment, blanching and cooling systems, dewatering and conveying systems etc. Our corn freezer can be used individually or match the complete corn freezing line. We offer technical support and installation guidance.

Whether you are processing IQF corn kernels or whole corn cobs, our engineering team can help you select the most suitable freezing solution based on your capacity, product type, and market requirements.

Contact us today to get a customized corn freezing solution.

Get in Touch Now!

AGICO tunnel freezer in the factory

AGICO tunnel freezer in the factory Final tunnel freezer for sale

Final tunnel freezer for sale