Tomato Paste Production Line

Tomato Paste / Tomato Sauce / Ketchup Production Line

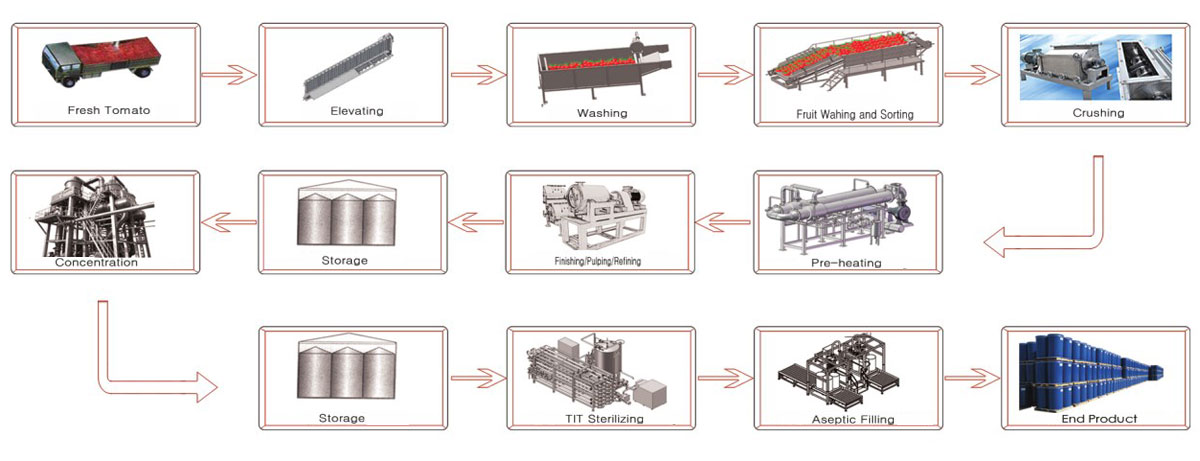

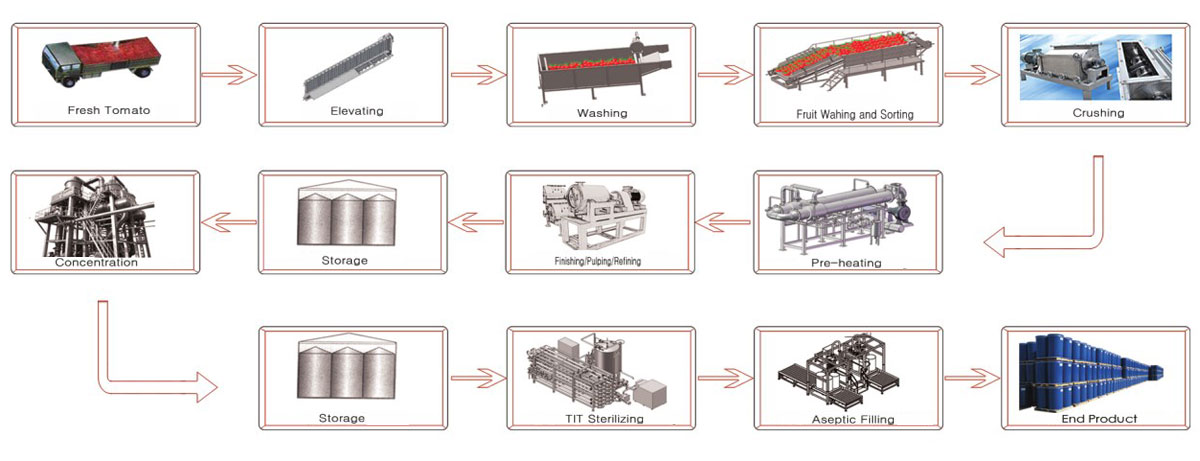

The tomato processing line is designed to convert fresh tomatoes into a refined, paste-like or sauce-like finished product through washing, crushing, pulping, concentrating, sterilizing, and filling.

Our tomato paste production line, also widely known as a tomato paste processing line, tomato sauce production line, or tomato ketchup production line, is a flexible and comprehensive processing system designed to produce a wide range of tomato-based products, including tomato paste, tomato sauce, and tomato ketchup. Whether you are targeting high-concentration tomato paste (28–30%, 36–38%), cooking-style tomato sauce, or flavored ketchup for retail markets, this tomato paste processing line allows you to achieve all products on the same equipment with minimal adjustments. By adjusting the concentration and adding different ingredients, the same tomato paste processing line can meet various market demands.

Tomato paste production line construction

Send Inquiry Now!

AGICO specializes in designing manufacturing and installation tomato paste or mango paste production line which can also process blackberry puree, strawberry puree, blueberry puree, apple puree, apricot paste, carrot paste, onion paste, chili paste and many other fruit jam just by changing some equipment.

Our tomato paste production line is equipped with elevator, washing system, sorting system, crushing system, pre-heater system, pulping system, vacuum concentration system, sterilizing system and aseptic filling system.

Tomato paste equipment can get final products with brix 28-30%, 30-32%, 36-38% or customized.

Tomato paste machines are equipped with capacity of 60t/day, 150t/day, 300t/day, 500t/day, 600t/day, 800t/day, 1000t/day, and 1500t/day.

Tomato paste production line flow chart

Tomato paste production line flow chart

Send Inquiry Now!

With a full set of advanced machinery: covering washing, crushing, pulping, concentrating, mixing, sterilizing, and filling, this tomato sauce production line delivers consistent quality, high efficiency, and long-term reliability for industrial production.

Our tomato paste production line is widely used in tomato processing factories, food enterprises, agricultural projects, and turnkey production plants around the world. Besides tomato ketchup production line, we also offer fruit juice production line such as orange juice production line, mango juice production line, apple juice production line etc. and food prcessing line like potato chips production line and banana chips production line.

Tomato paste / sauce / ketchup main processing procedures

Send Inquiry Now!

Advantages and Features of Tomato Paste Processing Line

-

All the machines of the tomato paste production line use food grade stainless steel, easy to clean.

-

We can customize different capacities of tomato paste production line according to customers requirements.

-

The color of finished tomato paste or sauce or ketchup is bright and the flavor is delicious.

-

AGICO tomato production line adopts advanced technology and complete supervision system to monitor each processing stage, which realizes low noise, simple operation and long service life.

-

Our tomato paste production line can produce tomato paste, which is achieved by vacuum concentration and packed in aseptic bags, drums or large containers. Also we produce tomato sauce by medium concentration, used for cooking and catering applications, with added sugar, vinegar, salt, spices, starch etc. Into tomato sauce, it becomes tomato ketchup which is commonly used with fries, fast food, and snacks.

-

AGICO tomato ketchup production line reduces investment cost and improves production flexibility.

Main Processing Machines and Procedures of Tomato Paste Processing Line

We provide a full set of tomato paste processing line machines from washing to filling. Our main machines included in the tomato paste processing line contain tomato washing machine, sorting conveyor, tomato crusher, preheating machine, pulping and refining machine, vacuum evaporator, mixing tank, homogenizer, deaerator, sterilizer(UHT / tubular type), filling machine (aseptic filler, bottle filler, sachet filler) and packing system. All machines can be customized according to required production capacity from 0.5–50 tons/hour.

Tomato Washing Machine

This is the beginning of the tomato production line, after selecting fresh tomatoes, to wash them with the

fruit and vegetable washing machine is necessary, especially in the large scale production of tomato paste, sauce or tomato ketchup. Our tomato washing machine can not only wash tomato, but also can wash kinds of other fruits and vegetables, it can work only or put into the tomato paste production line.

Tomato Sorting Machine

Quality control personnel or optical

sorting machine remove unripe or defective tomatoes to ensure stable product quality. Our tomato sorting machine is also used to grade other fruits and vegetables.

Tomato Crushing Machine

Tomato crushing machine breaks the fresh tomatoes into fine pulp for further processing. We offer high quality and food grade stainless steel tomato crusher for customers. This step is essential in both tomato paste processing lines and tomato sauce production lines.

Pre Heater for Tomato Production Line

Preheating system inactivates enzymes, improves color protection, and increases juice yield.

Tomato Pulping & Refining Machine

Pulping machine separates the skin, seeds, and fibers from the tomato pulp. This ensures a smooth, uniform texture that is required for tomato paste, tomato sauce, or ketchup products. The

pulping machine is also commonly used for pulping mangoes.

Tomato Vacuum Evaporator

The vacuum evaporator with single -effect, double-effect, or triple-effect, removes excess water at low temperature, preserving nutrients and color.

Depending on production needs, concentration levels can be adjusted to produce a range of tomato-based products like tomato paste and tomato sauce.

Homogenizer of Tomato Paste Production Line

A homogenizer improves texture stability and enhances product appearance, especially important for ketchup.

Tubular Sterilizer

High-temperature tubular sterilizers or UHT systems ensure microbial safety before filling.

Tomato Paste Filling and Packaging

The last step is to fill and package tomato paste or sauce or ketchup with suitable tomato paste filling and packaging machine, we offer different kinds of

packaging machines to packaging tomato paste with bags, cans, or some other containers.

Specification of tomato paste processing line

|

Raw material handling capacity(t/d) |

60 |

150 |

250 |

500 |

750 |

1000 |

1250 |

1500 |

2000 |

|

Evaporation Form |

Double

vacuum |

Double

vacuum |

Three

vacuum |

Three

vacuum |

Three

vacuum |

Three

vacuum |

Three

vacuum |

Three

vacuum |

Three

vacuum |

|

Water Consumption |

7.1 |

13.1 |

21.6 |

44.3 |

65.7 |

44.3 |

65.9 |

65.9 |

79.08 |

|

Power(kw) |

83.8 |

151.5 |

412.4 |

636.2 |

955.4 |

1291.6 |

1411.1 |

1558.1 |

1869.7 |

|

Steam Consumption(t/h) |

1.665 |

3.87 |

5.22 |

9.14 |

15.01 |

20.2 |

24.62 |

29.15 |

34.98 |

|

Compressed Air Consumption(t/h) |

66.2 |

66.2 |

66.2 |

72.2 |

72.1 |

72.2 |

72.2 |

72.2 |

86.84 |

|

Cooling Water Consumtion(t/h) |

125 |

317 |

307 |

585 |

825 |

1075 |

1410 |

1630 |

1956 |

Get in Touch Now!

Tomato paste production line flow chart

Tomato paste production line flow chart