Spiral IQF Freezer

Compact IQF Freezing Solution for Space-Limited Plants

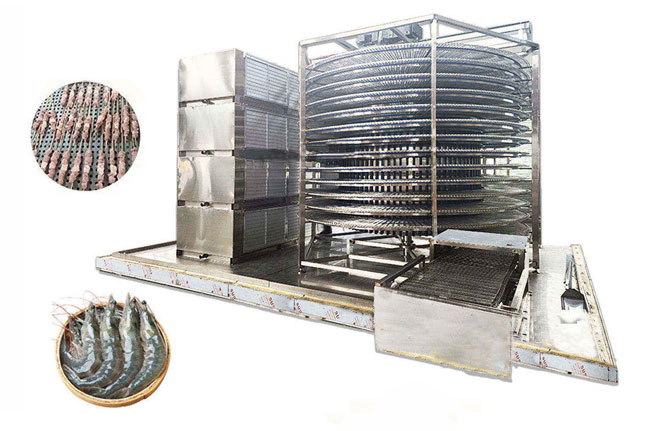

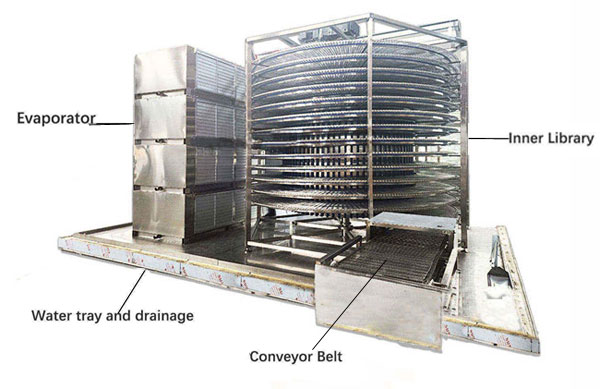

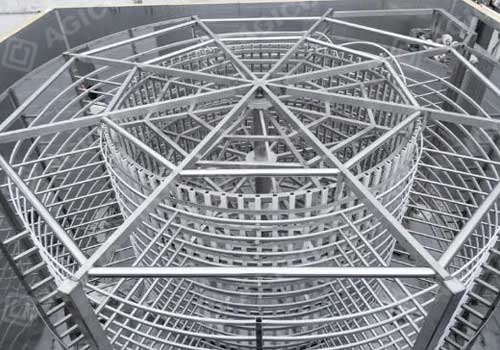

Spiral iqf freezer is just like iqf tunnel freezer, it is one of the individual quick freezing machines. Generally, spiral iqf freezer is energy efficient freezing equipment which can work continuously, with the help of stainless conveyor belt, products can be spiral rotated in the freezing room to realize the quick freeze. Due to the spiral structure, food which is waiting for freezing can stay longer time in the freezing room that finally can realize freezing evenly.

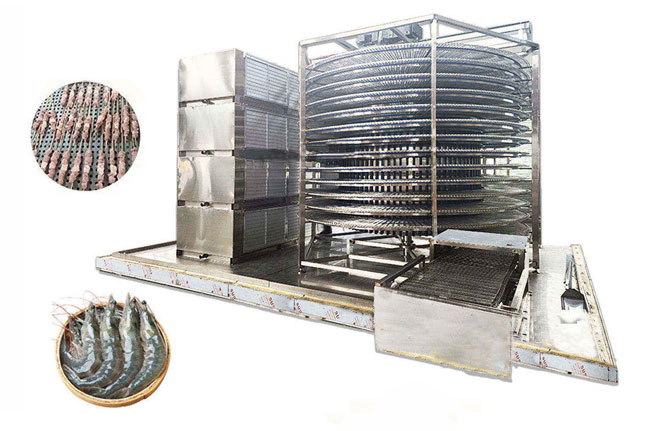

AGICO spiral iqf freezer is generally used in food industry. The spiral iqf freezer is compact because of the spiral conveyor belt design and vertical structure. So each spiral iqf freezer takes up a small area, makes it the ideal choice for some customers who have limited space. Now that spiral iqf freezer is one of the individual quick freezing machines, it can freeze the products individually, for example, when freezing shrimp meat, corn, bean etc.,each unit can be freezed only, avoid sticky to others.

WhatsApp

AGICO offers customized service, no matter which food you want to freeze, tell us your capacity, your space, your production situation, etc. Our technicists will design the most suitable freezing machine for you.

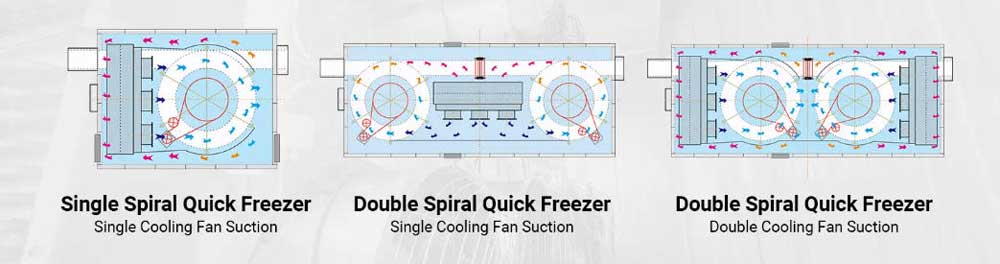

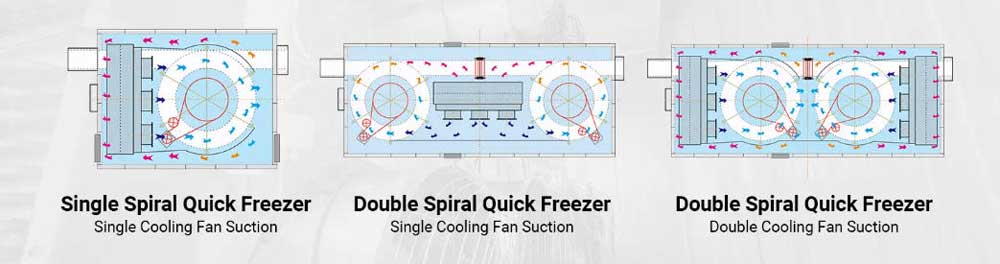

Types of Spiral IQF Freezer

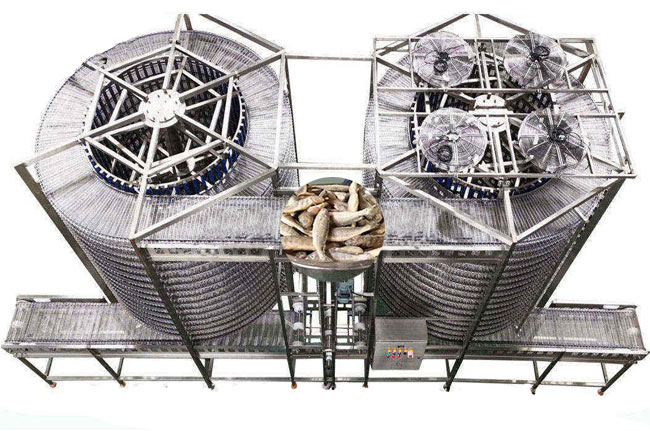

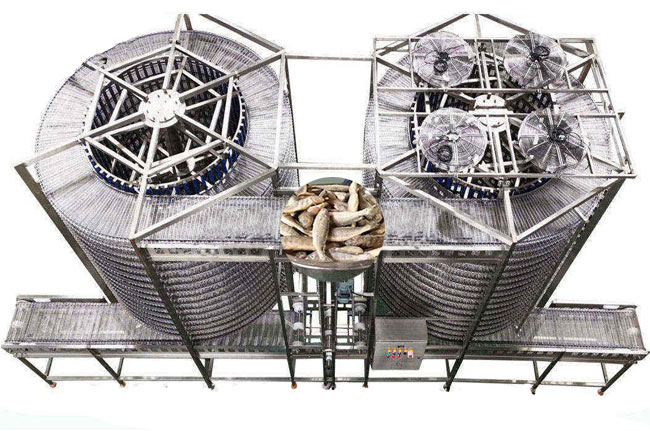

Generally speaking, there are two types of spiral iqf freezer, one is single drum spiral iqf freezer, the other is two drums spiral iqf freezer. According to different raw materials of the conveyor belt, spiral iqf freezer can be divided into spiral iqf freezer with stainless steel mesh belt and spiral iqf freezer with plastic mesh belt.

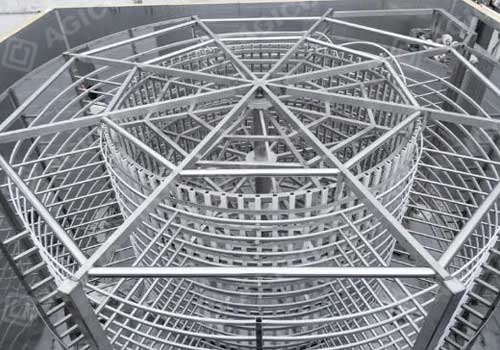

Different models of AGICO spiral freezer

Different models of AGICO spiral freezer

Just as the name replies, the main difference between single drum spiral iqf freezer and two drums spiral iqf freezer is the number of the spiral drum. It’s no doubt that the production capacity of single drum and double drums spiral iqf freezer is different. In general, the production capacity of single drum spiral iqf freezer ranges from 250kg/h to 3000kg/h, while the double drums spiral iqf freezer can produce products from 500kg/h to 6000kg/h.

Single drum spiral iqf freezer

Double drum spiral iqf freezer

Send Inquiry Now!

Applications of Spiral IQF Freezer

Like other freezing machines, spiral iqf freezer can be used to freeze many products which need longer freezing time and have more moisture, for example, spiral iqf freezer is available for meat products like beef, chicken, pork, burger patties, formed meat portions. What’s more, poultry products such as chicken wings, drumsticks, etc. fruits and vegetables like strawberries, beans, corns, broccoli and so on are also common application of spiral iqf freezer. Moreover, dumplings, shrimp, fish, meatballs etc. all are the raw materials of spiral iqf freezer. If you want our spiral iqf freezer, just tell us your products, your production capacity and your budget, we can customize the most suitable freezing equipment for you. If you have other food, we can also freeze according to your requirements.

Spiral IQF freezer application

Spiral IQF freezer application

Advantages of AGICO Spiral Freezer for Sale

-

Compact Structure with Smaller Space

Compared with tunnel freezer, spiral iqf freezer can save space up to 40%, while keeping high production capacity, it is suitable for food processing industry which has limited space but has high capacity requirement.

-

Uniform Freezing

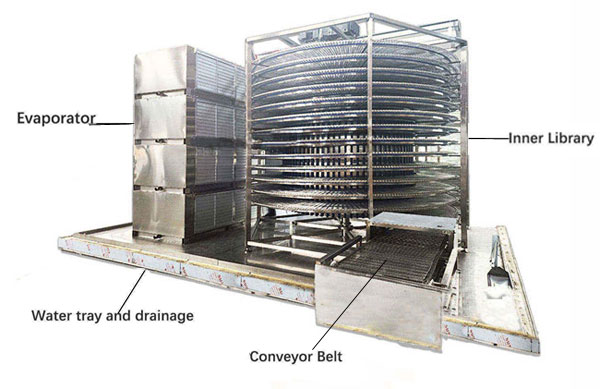

The internal airflow distribution of the spiral iqf freezer is reasonable and the temperature is stable, ensuring that the food is uniformly cooled throughout the freezing process. This effectively maintains the product's taste, texture and appearance. AGICO can also provide customized design solutions based on the actual products and production capacity requirements of the customers.

-

Energy-Saving Operation to Reduce Cost

The spiral iqf freezer is equipped with an automatic lubrication system, which can reduce lubricant consumption by approximately 20%. The efficient and energy-saving fan effectively lowers power usage. The stainless steel evaporator enhances heat exchange efficiency, helping users significantly save energy costs during long-term operation.

-

Safe Operation and Reliable Performance

Our spiral iqf freezer adopts mature European design concepts, combined with mechanical and electrical dual protection systems, ensuring stable and reliable operation, and capable of meeting the safety and durability requirements in continuous production environments.

-

Simple Operation and Maintenance

The operation interface is clear and intuitive, and employees can start working after simple training. The daily cleaning and maintenance procedures are designed reasonably, which can significantly reduce downtime and improve overall production efficiency.

-

Structural Design in line with Food Hygiene Standards

The entire spiral iqf freezer machine is made of stainless steel, with an inclined full-welded base structure, facilitating rapid drainage, reducing hygiene dead corners, having more internal space, and making cleaning more convenient, fully meeting strict food safety and hygiene regulations.

-

Widely Applications

Suitable for rapid freezing of various foods, including poultry products, seafood, baked goods, meat products, fruits and vegetables, as well as various pre-prepared and ready-to-eat foods, and can flexibly meet different production needs.

Spiral freezer freezing food

Single spiral freezer structure

Spiral freezer is freezing food

Spiral freezer construction

Spiral freezer inside structure

Spiral freezer cooling fan

Send Inquiry Now!

Specifications of AGICO Spiral IQF Freezer

|

Models |

AG-LSD1-500 |

AG-LSD1-1000 |

AG-LSD2-1000 |

AG-LSD2-1500 |

AG-LSD2-2000 |

AG-LSD3-3000 |

|

Capacity(kg/h) |

500 |

1000 |

1000 |

1500 |

2000 |

3000 |

|

Refrigeration capacity(kw) |

80 |

160 |

160 |

240 |

300 |

360 |

|

Size L×W×H(mm) |

6500x4440x3520 |

7000x5400x4200 |

12600x4440x3520 |

13800x5400x3670 |

13800x5400x4200 |

16260x6000x4510 |

|

Installed Power(kw) |

16.8 |

24.2 |

30 |

38 |

53 |

66 |

|

Feed temperature(℃) |

+15℃ |

|

Discharge temperature(℃) |

-18℃ |

|

Circulating temperature(℃) |

-35±2℃ |

|

Freezing Time(min) |

20~60 |

|

Refrigerants |

Customized |

Get a Customized Spiral IQF Freezer Solution

Choosing the right spiral freezer requires careful evaluation of product characteristics and factory layout.

Our engineering team provides:

Free project consultation.

Customized spiral freezer design.

Complete IQF line integration support.

Contact us with your product details, production capacity, and available space, and we will recommend the most suitable spiral IQF freezing solution for your facility.

Get in Touch Now!

Single drum spiral iqf freezer

Single drum spiral iqf freezer Double drum spiral iqf freezer

Double drum spiral iqf freezer Spiral IQF freezer application

Spiral IQF freezer application Spiral freezer freezing food

Spiral freezer freezing food Single spiral freezer structure

Single spiral freezer structure Spiral freezer is freezing food

Spiral freezer is freezing food Spiral freezer construction

Spiral freezer construction Spiral freezer inside structure

Spiral freezer inside structure Spiral freezer cooling fan

Spiral freezer cooling fan