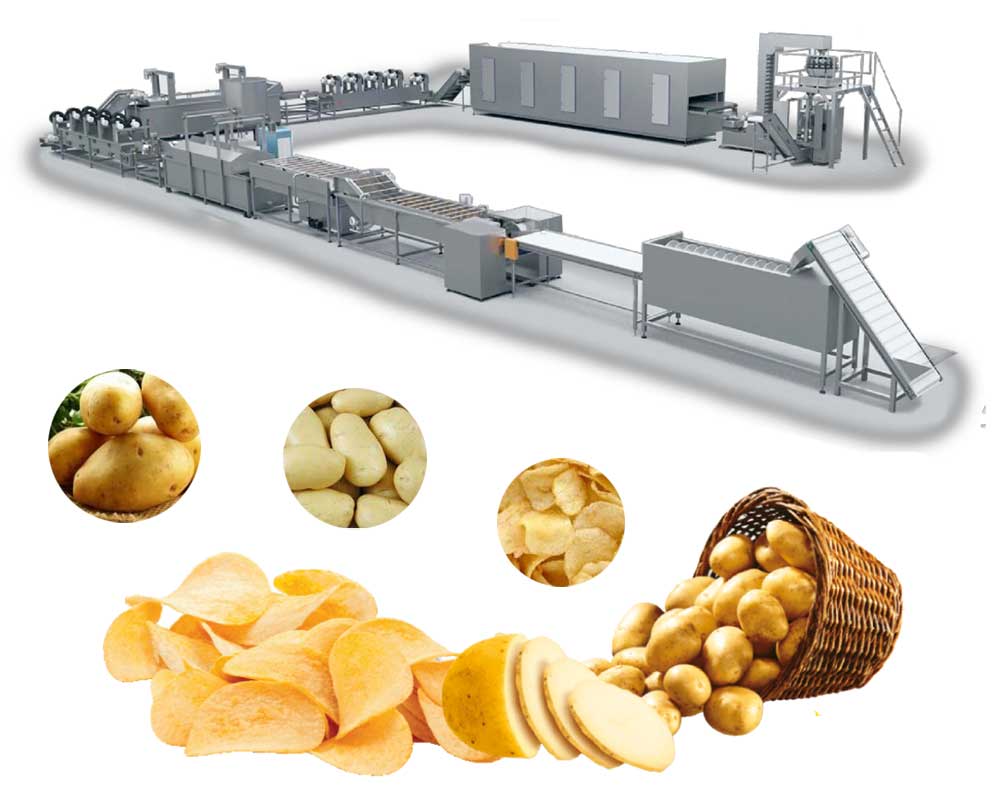

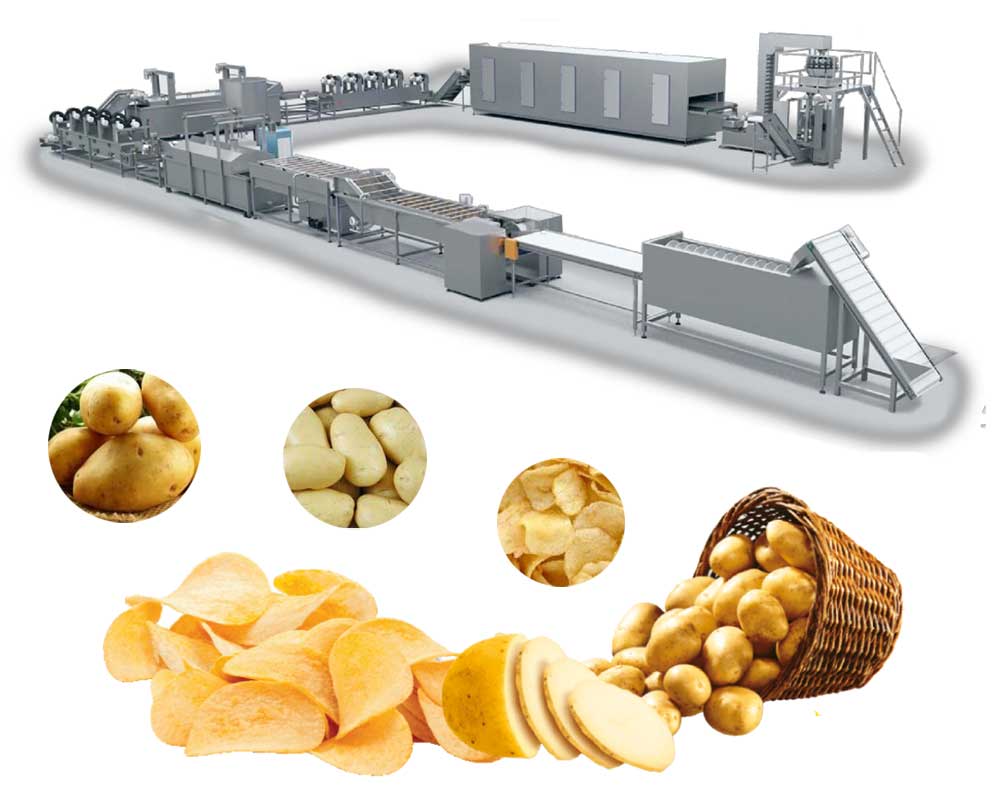

Potato Chips Production Line

Potato Chips Production Line Overview

In the food processing industry, potato chips are one of the most common snacks. In English-speaking countries such as the United States and the United Kingdom, they are usually called potato chips, while in South Asian and Southeast Asian countries like India and Pakistan, people prefer the call potato wafers. Regardless of the name, both refer to a popular snack made from thinly sliced potatoes.

Send Inquiry Now!

The potato chips production line is an automated processing system specially designed for the mass production of potato chips (or potato wafers). This potato chips production line integrates multiple processes including washing, peeling, slicing, blanching, dewatering, frying, deoiling, seasoning, and packaging, achieving a continuous production flow from fresh potatoes to finished potato chips. It is widely used in snack food processing factories, potato chip brands, and food OEM plants.

Potato chips production line and used machine in each procedure

Send Inquiry Now!

When mentioned potato chips making machine, it not only refers to one potato wafer making machine, but the whole chips making machines that needed during the potato chips making. While for your potato chips making, you can choose the whole potato chips production line or the single potato chips making machine, such as you only need frying machine or washing and peeling machine, it's no problem, our company can supply full automatic potato chips production line, semi automatic potato chips production line and one of the potato chips making machines, you can choose the suitable potato wafer making machines according to your need.

Advantages of AGICO Potato Chips Production Line

-

We offer various output capacities like 30kg/h, 50kg/h, 100kg/h, 150kg/h, 250kg/h, 350-400kg/h, 500-800kg/h, 800-1000kg/h, 1200-2000kg/h etc. No matter the high capacity of automatic potato chips production line, or the semi automatic potato wafer making machine, we can customize each potato chips making machine to meet your requirements.

-

The proportion of potatoes and final potato chips is about 4:1. The final potato chips have a good shape with a smooth surface and uniform thickness. Besides, the thickness of potato chips are adjustable according to your requirements.

-

The automatic potato chips production line is fully automatic and easy to operate, only need 6-8 person to operate each potato chips making machine, so it improves the production efficiency.

-

All the potato chips making machines are made of stainless steel, which makes it safe, clean and healthy.

-

Our potato chips making machine line can also be used to make french fries by changing the potato chips cutting machine and add the freeze fryer machine. What’s more, cassava, banana, carrots and so on can be processed as raw materials.

-

Electricity power requirement of the potato chips production line is 380V, 50Hz, three-phase. But we can make the potato chips production line as per your local voltage. Please confirm the voltage before production.

Main Potato Chips Making Machine

When processing potatoes into potato chips, there are many chips making machine in the whole potato chips production line, among all the making machine, the

chips frying machine is the most important equipment. But other chips making machine is also important, they work together to make high quality potato chips, to choose the proper potato wafer making machine according to your requirements. The following is the main potato chips making machine used during the potato chips production line.

Potato chips making machine elevator

Potato chips washing and peeling machine

Potato chips sorting and conveyor

Potato chips cutting slicing machine

Potato slices washing machine

Potato chips blanching machine

Potato chips dehydrator machine

Potato chips frying machine

Potato chips deoiling machine

Potato chips flavoring or seasoning machine

Packaging machine of potato chips production line

Main Production Process of Potato Chips Production Line

The potato chips production line is designed for the continuous and high efficiency production of high-quality fried potato chips. The entire process: from raw potato to finished crispy chips, includes several key stages: washing, peeling, slicing, rinsing, dehydration, frying, and packaging. Each stage is supported by specialized potato chips making machines to ensure high efficiency, consistent quality, and hygienic operation.

1. Raw Material Selection

Select fresh, high-starch potatoes with uniform sizes (50–70 mm in diameter). Potatoes should be clean, free from sprouts, rot, and pests. High dry matter potatoes ensure a better crispiness and golden color after frying.

2. Washing & Peeling (Potato Washing and Peeling Machine)

The raw potatoes are washed to remove dirt. Using a mechanical friction peeling system, the potato

washing and peeling machine can process 30–40 kg at a time. Peeling time is usually between 3–8 minutes depending on the freshness of the potatoes. Proper peeling keeps the potato surface smooth while minimizing raw material loss.

3. Slicing (Potato Slicing Machine)

Clean potatoes are evenly fed into the potato slicing machine or called potato cutting machine, which cuts them into uniform slices of 1–2 mm thickness. Adjustable blades ensure the desired thickness for different product styles, whether for potato chips or wafers.

4. Blanching (Food Blancher)

The sliced chips are blanched by

food blancher in clean water immediately to prevent oxidation and browning. This process also removes surface starch, helping to maintain the quality of frying oil and improve the final chip color and texture.

5. Dehydration (Dewatering Machine)

The blanched potato slices are passed through a dewatering machine or

dehydrator to remove excess surface moisture. This step shortens frying time, reduces oil absorption, and improves the crispness of the final chips.

6. Frying (Chips Frying Machine)

The

chips frying machine is the core equipment of the line. Potato slices are evenly fed into the oil tank where the temperature is maintained between 180–200°C (356–392°F). The frying time is controlled within 2 minutes to ensure even color and crisp texture. Palm oil is widely used due to its excellent stability, long life, and suitability for deep frying.

7. Deoiling, Seasoning & Packaging

After frying, excess oil is removed using a

de-oiling machine, followed by uniform flavoring in the seasoning machine. Finally, the chips are packed by an automatic packing machine, ready for distribution and sale.

Main Potato Chips Making Machines Specification

|

Name |

Parameters |

|

Potato Washing and Peeling Machine |

Power: 0.75kw Voltage: 380V-3/220V-3

Weight: 90KG

Size: 650*550*800mm

Capacity: 200KG/H |

|

Potato Cutting Machine |

Power: 1.1kw

Voltage:380v-3/220v-3

Weight: 110KG

Size: 950*900*1000mm

Capacity: 600KG/H |

|

Blanching Machine |

Power: 9kw

Volts: 380v-3/220v-3 Weight: 80KG

Size: 700*700*900mm

Capacity: 60KG/H |

Dewater Machine |

Power: 1.5kw

Volts: 380v-3/220v-3 Weight: 300KG

Size: 900*500*800mm

Capacity: 200KG/H |

|

Pottato Frying Machine |

Power: 12kw

Volts: 380v-3/220v-3 Weight: 80KG

Size: 700*700*900mm

Capacity: 20KG/H |

|

De-oiling Machine |

Power: 1.1kw

Volts: 380v-3/220v-3 Weight: 300KG

Size: 900*500*800mm

Capacity: 200KG/H |

|

Potato Flavoring Machine |

Power: 1.1kw

Volts: 380V-3/220V-3

Weight: 150KG

Size: 1100*800*1300

Capacity: 200KG/H |

|

Vacuum Packing Machine |

Power: 1.1kw

Volts: 380V-3/220V-3

Weight: 80kg

Size: 500*500*800mm

Capacity: 20KG/H |

Get in Touch Now!

Potato chips cutting slicing machine

Potato chips cutting slicing machine

Potato chips flavoring or seasoning machine

Potato chips flavoring or seasoning machine Packaging machine of potato chips production line

Packaging machine of potato chips production line