Commercial Food Dehydrator

In the modern food processing industry, the commercial food dehydrator or industrial food dehydrator machine has become an indispensable piece of equipment. By precisely controlling temperature and airflow, it effectively removes moisture from foods while preserving their nutritional value and flavor. This makes it an ideal solution for processing fruits, vegetables, meats, seafood, and other agricultural products.

In industries that emphasize nutrient retention, such as dried fruit, vegetable chips, or beef jerky production, the commercial food dehydrator is one of the most commonly used machines. Meanwhile, a commercial dryer can also be applied in other fields, including dehydratingherbal materials and chemical raw ingredients. Therefore, the AGICO commercial food dehydrator product line covers everything from compact dehydrators to cabinet dryers and continuous belt dehydrating systems.

What Is a Commercial Food Dehydrator?

A commercial food dehydrator or industrial food dehydrator is a machine that removes moisture evenly from food through hot air circulation or other dehydrating methods. It features a food-grade stainless steel structure, intelligent temperature control system, and high-efficiency circulating fan to ensure a stable, safe, and energy-efficient dehydrating process. Compared with household dehydrators, it offers higher capacity, greater temperature precision, and longer service life.

For fruit and vegetable processing plants, commercial dehydrator machines are often used with juicers, pulp concentrators, and pasteurizers. During juice production, the dehydrator can be used to dry fruit pulp and peels into dried fruit or tea ingredients, as well as reduce the moisture content of byproducts for easier storage and transportation.

Large commercial industrial food dehydrator

Commercial food dehydrator with trolley

Common industrial food dehydrator

Belt type industrial food dehydrator

Send Inquiry Now!

Why Choose AGICO Industrial Food Dehydrator

As a professional manufacturer, AGICO provides industrial-grade commercial food dehydrator machines designed for large-scale food production. These machines feature excellent dehydration performance, efficiently removing water and humidity from various materials. Their outstanding reliability and energy efficiency make them a key component for improving productivity and extending food shelf life.

As a leading manufacturer of commercial food dehydrator machines, AGICO offers a complete range of heat pump food dehydrators: from cabinet-type dehydrator to continuous belt food dehydrator machines. Customized solutions are available to meet your specific capacity, space, and product requirements.

AGICO food dehydrator factory

Observe food dehydrator inside situation at any time

Advantages of AGICO Commercial Food Dehydrator

-

Wide Application Range

AGICO commercial food dehydrator is suitable for dehydrating a variety of foods, especially fruits and vegetables such as apples, bananas, persimmons, mangoes, lemons, pineapples, strawberries, tomatoes, and chili peppers etc. During dehydrating, the foods do not crack, discolor, deteriorate, or oxidize. The process ensures thorough dehydration while maximizing the retention of vitamins, aroma, and natural color. Different airflow directions can be selected to achieve optimal dehydrating efficiency under various process conditions.

-

Intelligent Control System

Equipped with a color touchscreen controller for precise temperature and humidity control. The system allows users to set dehydrating time and view real-time data inside the dehydrating chamber. Once the process is complete, the food dehydrator stops automatically. With automatic temperature control and dehumidification, heat loss is minimized, achieving a heat utilization rate above 80% for remarkable energy savings. Different food types can be matched with tailored temperature settings.

-

Hygienic and Durable Design

AGICO industrial commercial food dehydrator machine is made entirely of food-grade stainless steel, the dehydrator is easy to operate, clean, and maintain.

-

Energy-Saving and Reliable Operation

The overall structure of our food dehydrator is compact and user-friendly, ensuring long service life and stable performance. Multiple heating options are available: electric, steam, or gas. Certified by ISO 9001, the optimized design improves heat efficiency from the traditional 3–7% to 35–45%, with maximum heat efficiency up to 50%.

Food dehydrator machine fan

Commercial food dehydrator trays

Food dehydrator PLC control system

Send Inquiry Now!

Commercial Food Dehydrator Specifications

|

Model |

AGHX1-1 |

AGHX2-2 |

AGHX2-4 |

AGHX3-6 |

AGHX4-8 |

|

Quantity of dryer |

1 |

2 |

4 |

6 |

8 |

|

Quantity of drying tray |

24 |

48 |

96 |

144 |

192 |

|

Circulating fan |

1 |

1 |

2 |

3 |

4 |

|

Hydrofuge fan |

1 |

1 |

1 |

1 |

2 |

|

Power (kW) |

12 |

18 |

30 |

48 |

60 |

|

Dimension (meters) |

1.6×1.2×2.35 |

2.5×1.2×2.35 |

2.5×2.2×2.35 |

3.5×2.2×2.35 |

4.8×2.2×2.35 |

|

Net weight (kg) |

470 |

760 |

1000 |

1650 |

2000 |

|

Packing dimension (meters) |

1.72×1.36×2.26 |

2.63×1.36×2.26 |

2.63×2.26×2.26 |

3.63×2.26×2.26 |

4.93×2.26×2.26 |

|

Packing weight (kg) |

520 |

830 |

1100 |

1800 |

2150 |

|

Capacity (kg) |

72 |

144 |

288 |

432 |

576 |

Heat Pump Dehydrating Room

Besides mesh belt dryer and fruit drying oven, there is another dehydrating equipment, it is the heat pump dehydrating room. The heat pump dehydrating room is a type of gentle and efficient dehydrating equipment designed to address common issues in traditional dehydration processes, such as discoloration, deterioration, cracking, uneven moisture distribution, and contamination. It ensures that the dried products retain a plump shape, vibrant color, and glossy appearance.

Compared with conventional drying equipment, the heat pump dehydrating room offers automatic operation, eliminating the need for manual intervention. It features precise temperature and humidity control, automatic dehumidification, and ultra-low operating costs, making it an ideal modern solution for drying food, meat products, seafood, fruits, vegetables, and agricultural by-products.

Send Inquiry Now!

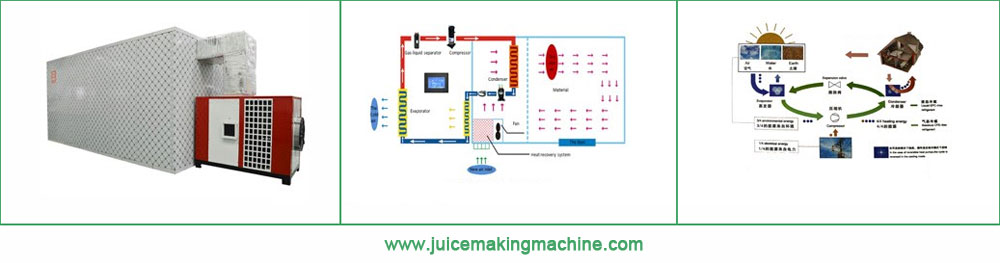

Heat Pump Dehydrating Room Working Principle

The working process of a heat pump dehydrating room relies on the heat exchange cycle. The refrigerant is compressed by the compressor into a high-temperature, high-pressure gas, which then enters the condenser to release heat. This heat is circulated into the drying chamber by a fan, heating the air inside up to 75°C. As the air temperature rises, moisture in the materials gradually evaporates and is removed by a fresh-air dehumidification system, achieving efficient dehydration.

The system uses high-quality insulation materials for the drying chamber, minimizing heat loss and improving energy efficiency. With automatic temperature and humidity regulation, it offers precise, flexible, and convenient control. The closed-loop hot air circulation design reduces energy waste, while the heat recovery and secondary evaporator cycle further enhance the heat pump’s performance, increasing the coefficient of performance and reducing overall energy consumption.

Energy Saving Principle

At the core of the system is an air-source heat pump, which operates based on the reverse Carnot cycle principle. It absorbs heat from the surrounding environment—air, water, or soil—and transfers it to the drying materials. Remarkably, up to three-quarters of the required energy comes from the air itself, making it an eco-friendly and cost-effective drying solution.

Get in Touch Now!