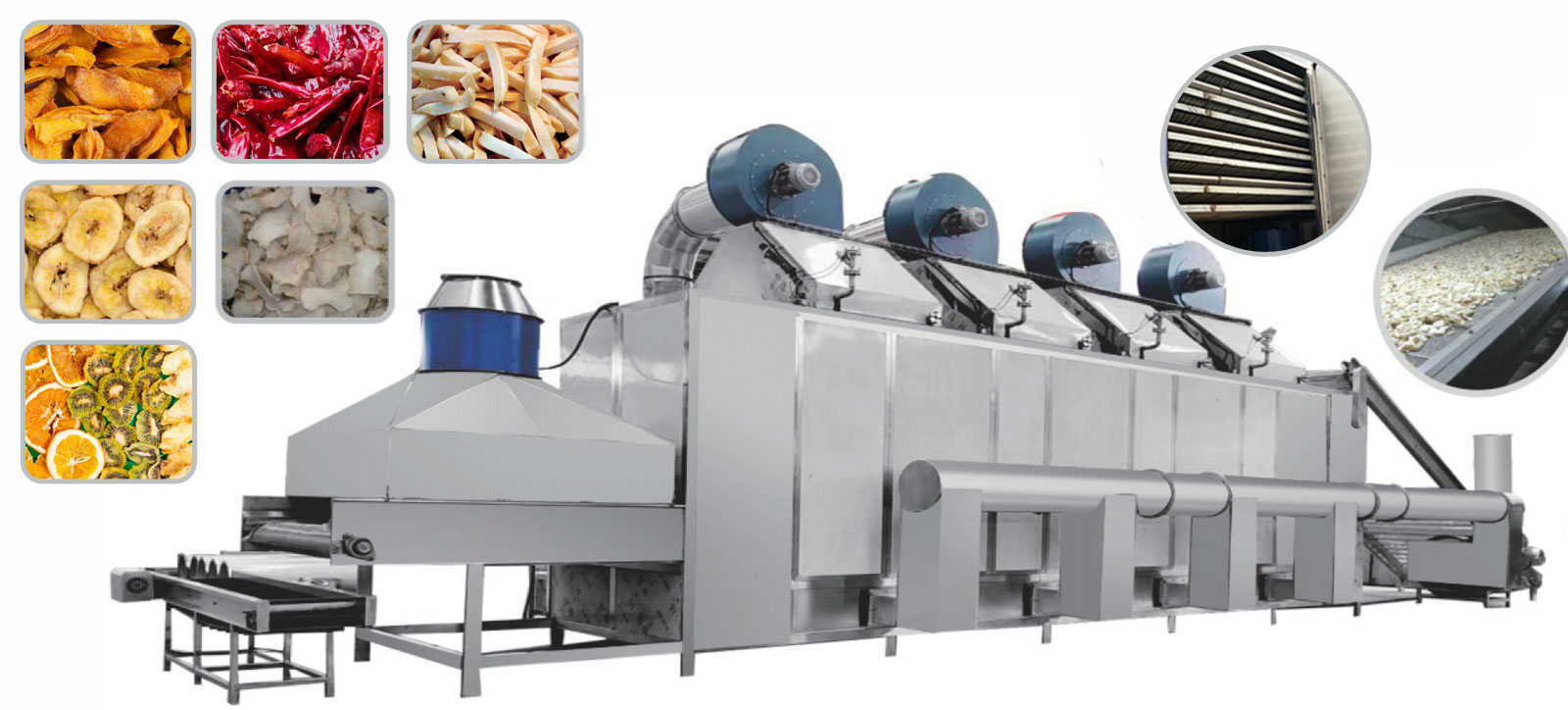

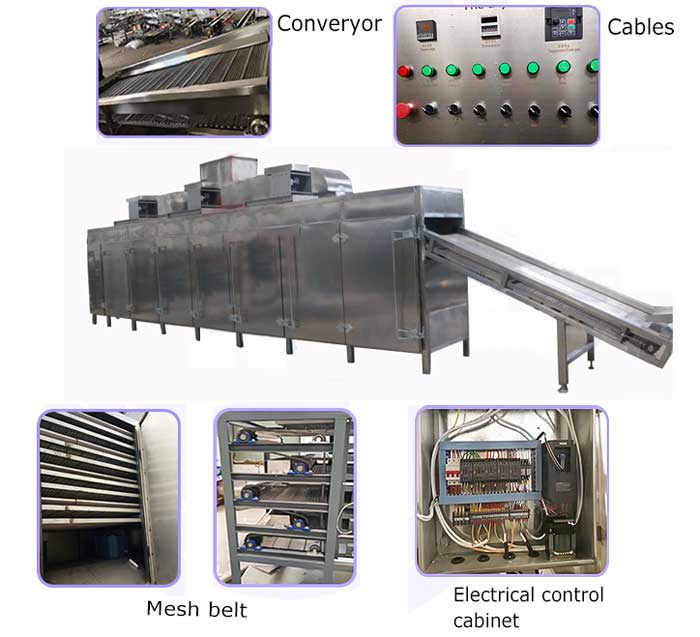

Mesh Belt Dryer

What is a Mesh Belt Dryer?

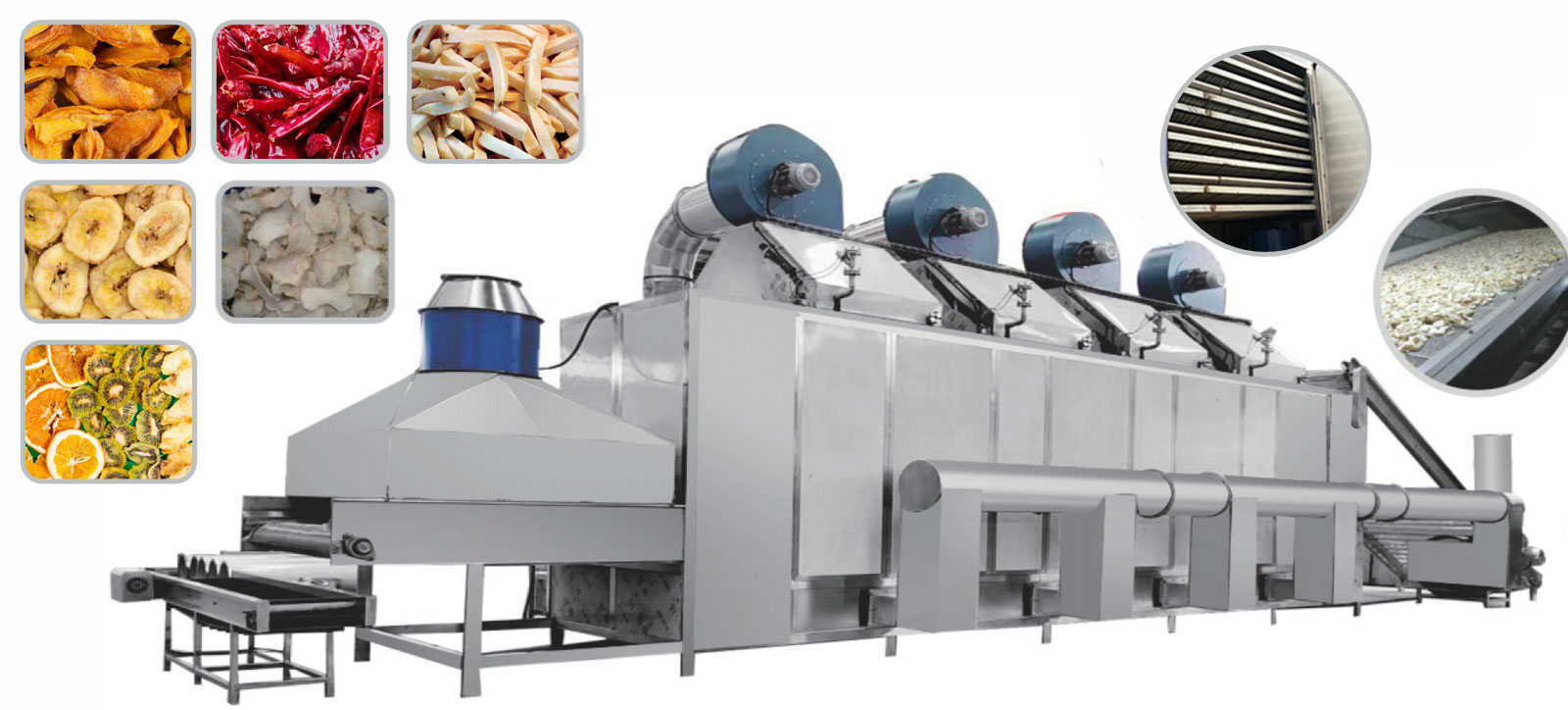

A mesh belt dryer refers to a drying machine that uses stainless steel wire mesh (commonly 12–60 mesh) as a conveyor belt. Through one or more conveying belts moving slowly inside the dryer, it completes the drying of vegetables and fruits. The mesh belt dryer is suitable for drying small particles, slices, and strip-shaped materials (such as chili flakes, vegetable slices, dried fruits, seaweed, etc.). It can achieve continuous feeding and continuous discharging, making it ideal for large-scale, assembly-line production. It is especially suitable for materials with large output, high initial moisture content, and that require low-temperature drying. We offer other fruit drying oven of CT-C series for customers to choose according to the real situation.

The mesh belt dryer is a type of continuous belt dryer, particularly suitable for low-temperature, large-surface materials with high ventilation requirements. Hot air passes through the material layers, achieving heat and mass transfer, and removing moisture. In the food and agricultural product drying industry, many continuous drying machines adopt the mesh belt structure to dry materials requiring color and nutrient retention under low or medium temperatures. The core advantages of a mesh belt dryer are excellent ventilation, uniform drying, and minimal damage to material shape. If your materials require low-temperature, uniform drying in slice or particle form, the mesh belt dryer is the best choice.

Send Inquiry Now!

Send Inquiry Now!

Why Choose a Mesh Belt Dryer?

-

Excellent Ventilation & Uniform Drying: The structure of mesh belt dryer allows hot air to penetrate materials from top to bottom, ensuring uniform heating for sliced, strip-shaped, or granular fruits and vegetables, avoiding under-drying or over-drying in certain areas.

-

Low-Temperature Drying to Preserve Nutrients & Color: Fruits and vegetables require temperature control (generally 40–80°C) during drying to prevent the destruction of vitamins, flavors, and color by high heat. A mesh belt dryer can use multi-stage temperature control for gentle dehydration.

-

Ideal for Large-Scale Continuous Production: Multiple layers of material can be laid for continuous feeding and discharging, making mesh belt dryer suitable for factory production of dried fruits, mushrooms, garlic slices, dried chili, and more.

-

Strong Adaptability: For different fruits and vegetables (such as apple slices, dried mango, banana chips, carrot slices, kelp strips, etc.), only the belt speed, hot air temperature, and airflow need to be adjusted—no need to replace the entire mesh belt dryer.

Working Principle of a Mesh Belt Dryer

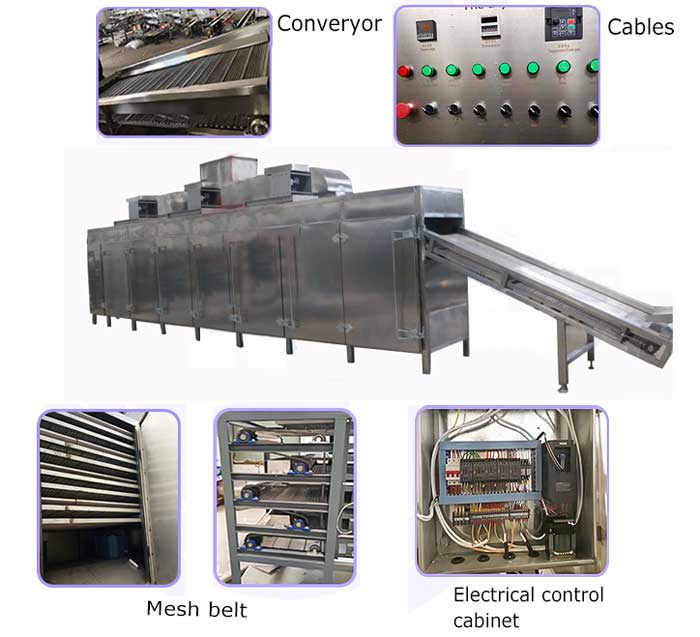

In a multi-layer mesh belt dryer, fruits and vegetables are evenly spread on the belt by a feeder. The belt, typically made of 12–60 mesh stainless steel wire mesh, is driven by a transmission device to run inside the dryer.

The dryer consists of multiple units, each with independent hot air circulation. Part of the exhaust gas is discharged via a special moisture removal fan, with the exhaust volume controlled by an adjustment valve. Hot air passes through the belt from top to bottom or bottom to top, transferring heat and mass to remove moisture. Belt speed is slow and adjustable according to the material and temperature requirements. Dried products continuously fall into a collector. Upper and lower circulation units can be freely configured, and the number of units can be customized.

Send Inquiry Now!

Send Inquiry Now!

Why Choose AGICO Mesh Belt Dryer?

Professional Team

AGICO has a high-level team including experts, professors, and senior engineers, with advanced machinery and the ability to meet diverse customer needs. Certified with ISO9001, CE, and holding over 50 patents with import/export rights.

Customizable Design

We tailor solutions for each client, offering different heating methods (electric, steam, hot air) and custom production capacities.

Advanced R&D

Constantly introducing advanced international technology, integrating it with the domestic market, and developing high-performance dryers.

Global Service

80+ service engineers worldwide, offering 24/7 year-round service with fast response and on-site installation, training, and maintenance.

Modern Facilities

40,000㎡ factory area, 25,000㎡ standardized workshops, 60+ advanced processing machines, direct factory supply, and competitive prices.

Our mesh belt dryer mainly consists of a conveyor mesh belt, an automatic feeder, and a main drying unit. It features automatic feeding, automatic discharge, and automatic control functions, offering advantages such as low heat consumption, high production efficiency, easy operation, simple maintenance, and wide applicability.

For example, our specialized chili drying system adopts a unique hot air circulation method with automatic temperature control and even hot air distribution, which not only saves energy but also improves drying efficiency. The design effectively prevents color changes in chilies during drying, and the equipment is easier to clean.

In addition, our vegetable dryers allow for adjustable drying area, air pressure, airflow, drying temperature, and mesh belt speed to match the characteristics and quality requirements of different vegetables. They are widely used for drying various regional and seasonal vegetables and fruits, such as garlic slices, pumpkin, konjac, white radish, yam, and bamboo shoots.

Food & Fruit/Vegetable Drying Equipment Recommendation Table

|

Product Type |

Recommended Drying Method |

Recommended Dryer |

Recommended Temp. Range |

Features & Advantages |

|

Apple slices, dried mango, banana chips, etc. |

Low-temp hot air drying |

Mesh Belt Dryer |

45–65℃ |

Preserves aroma and color, avoids nutrient loss, multi-layer belt for even drying |

|

Carrot slices, onion flakes, garlic slices, etc. |

Multi-stage temperature control drying |

Multi-layer Mesh Belt Dryer |

50–75℃ |

Step-by-step moisture removal, prevents surface hardening, keeps crisp texture |

|

Chili, shiitake mushrooms, black fungus, etc. |

Low-temp hot air circulation drying |

Mesh Belt Hot Air Dryer |

45–70℃ |

Prevents discoloration, retains aroma, adjustable airflow & temperature |

|

Seaweed, carrageenan, kelp strips, etc. |

Fully enclosed multi-stage hot air drying |

Fully Enclosed Mesh Belt Dryer |

80℃ → 90℃ → 120℃ |

Multi-stage drying for quick dehydration, maintains product shape |

|

Potato chips, French fries, etc. |

Hot air + frying drying |

Frying Type Continuous Belt Dryer / Hot Air Belt Dryer |

60–90℃ |

Pre-fry then low-temp drying, keeps crispy texture |

|

Nuts (cashew, almond, etc.) |

Medium-temp hot air drying |

Chain Plate or Steel Belt Dryer |

70–110℃ |

Suitable for hard-shell foods, even heat transfer, high efficiency |

How to Choose the Right Fruit and Vegetable Dryer Machine

For sliced, strip-shaped, or granular fruits and vegetables → Mesh Belt Dryer is the first choice.

For fruits and vegetables with high color and aroma requirements → choose low-temperature, multi-stage drying.

For high output and continuous production → choose a multi-layer continuous mesh belt dryer.

For non-food or high-temperature rapid drying materials (such as certain nuts or baked goods) → consider other types of continuous belt dryers or hot air circulation ovens.

Mesh Belt Dryer Drying Process

-

Feeding – Wet materials enter via a feeding device of the mesh belt dryer, are evenly spread by a distributor, and enter from the top of the dryer.

-

Conveying – Materials move layer-by-layer from top to bottom inside the dryer.

-

Drying – Heat from the bottom flows upward through each mesh layer, ensuring thorough hot air contact and efficient heat exchange.

-

Moisture Removal & Discharging – Moisture is evaporated and discharged from the top; dried materials exit through the discharge outlet.

In the food processing field, especially for fruits and vegetables drying, selecting the right drying equipment is key to product quality.

AGICO offers multiple drying solutions including mesh belt dryers, fruit drying oven, multi-layer continuous dryers, and chain plate dryers. Whether you require low-temperature preservation, rapid dehydration, or large-scale continuous production, we provide efficient and energy-saving equipment selection advice. If you have fruit and vegetable drying needs, contact us and we will serve you wholeheartedly.

Specification of AGICO Mesh Belt Dryer

|

Parameter |

GC-DW-1.2-8 |

GC-DW-1.2-10 |

GC-DW-1.6-8 |

GC-DW-1.6-10 |

GC-DW-2-8 |

GC-DW-2-10 |

|

Quantity of Unit |

4 |

5 |

4 |

5 |

4 |

5 |

|

Belt Width (m) |

1.2 |

1.2 |

1.6 |

1.6 |

2 |

2 |

|

Length of Drying Section (m) |

8 |

10 |

8 |

10 |

8 |

10 |

|

Thickness of raw material spreading |

10-80mm |

|

Operation Temperature |

60-130℃ |

|

Steam Pressure (Mpa) |

0.2-0.8 |

|

Steam Consumption (kg/h) |

120-300 |

150-375 |

150-375 |

170-470 |

180-500 |

225-600 |

|

Drying Time (h) |

0.2-1.2 |

0.25-1.5 |

0.2-1.2 |

0.25-1.5 |

0.2-1.2 |

0.25-1.5 |

|

Drying Efficiency (kg h2o/h) |

60-160 |

80-220 |

75-220 |

95-250 |

100-260 |

120-300 |

|

Power of Fan (Kw) |

9.9 |

12.1 |

9.9 |

12.1 |

18.2 |

22.2 |

|

Total Power (Kw) |

11.4 |

13.6 |

11.4 |

13.6 |

19.7 |

23.7 |

”

Get in Touch Now!