IQF Tunnel Freezer

High-Capacity Continuous Freezing Solution for IQF Food Processing

An IQF tunnel freezer is a specialized freezing system designed for products that need to be frozen individually rather than in blocks. Unlike conventional freezing methods, IQF technology ensures that each piece of food is frozen separately, without sticking or clumping together. IQF tunnel freezer uses high-velocity cold air to freeze small, discrete food pieces individually as they move through a straight tunnel on a conveyor belt.

IQF tunnel freezers are widely used in industrial food processing plants where high throughput, stable operation, and consistent product quality are required. The common applications of iqf tunnel freezer contain fruits, vegetables, seafood, and small meat products where product appearance, texture, and flowability are important.

Most industrial IQF freezers are designed in tunnel configurations to ensure continuous operation, uniform freezing, and high production efficiency.

Request an IQF Freezing Solution

Application of IQF Tunnel Freezer

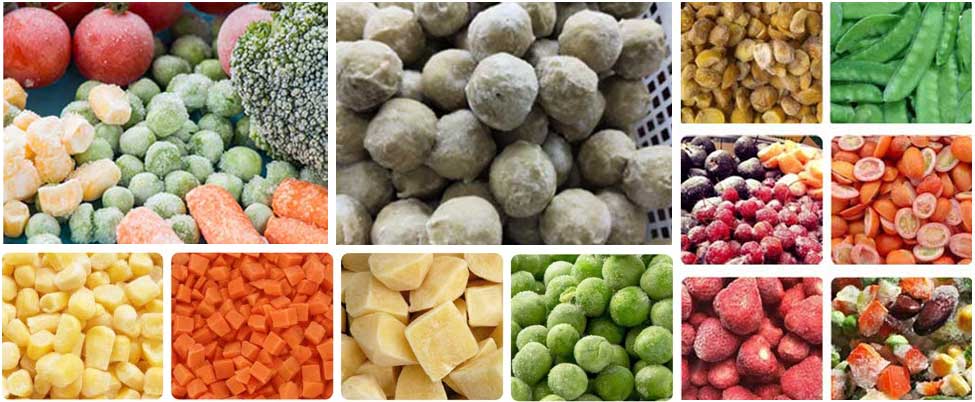

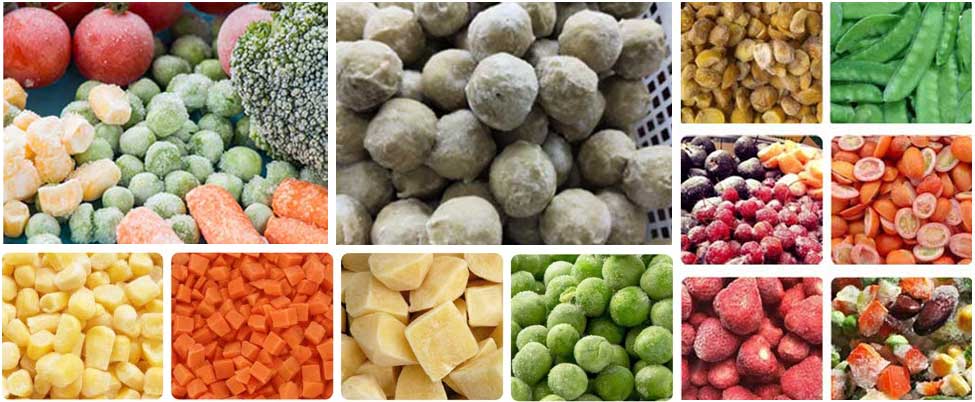

IQF tunnel freezers are mainly used for small, discrete food items. Typical products processed by IQF tunnel freezer are as follows:

-

Frozen vegetables: green peas, sweet corn, green beans, diced carrots, mixed vegetables etc.

-

Fruits: blueberries, strawberries, mango cubes, pineapple pieces, and so on.

-

Seafood: shrimp, squid rings, fish cubes.

-

Meat and poultry: diced chicken, beef cubes, processed meat pieces etc.

These products require rapid surface freezing to prevent sticking, dehydration, or deformation during processing and packaging.

IQF tunnel freeazer application

How does an IQF Tunnel Freezer Work?

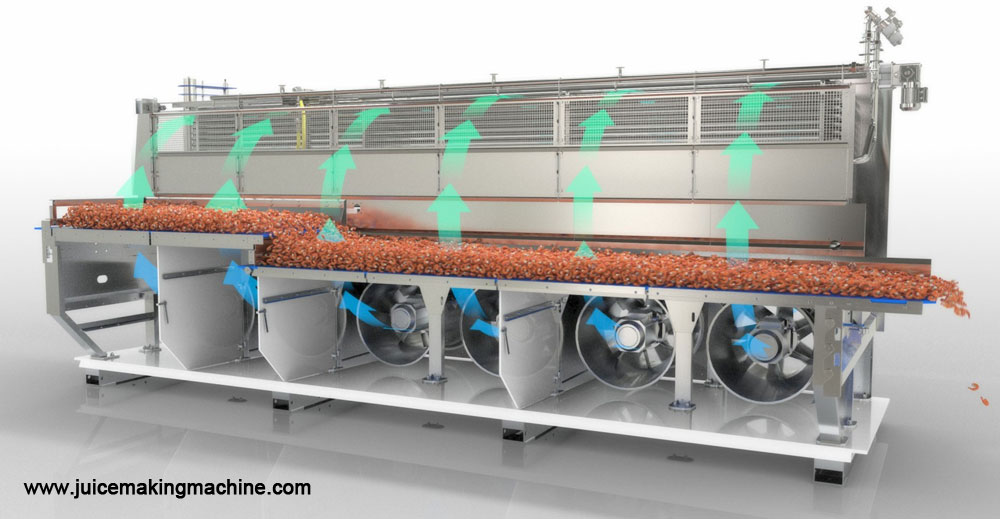

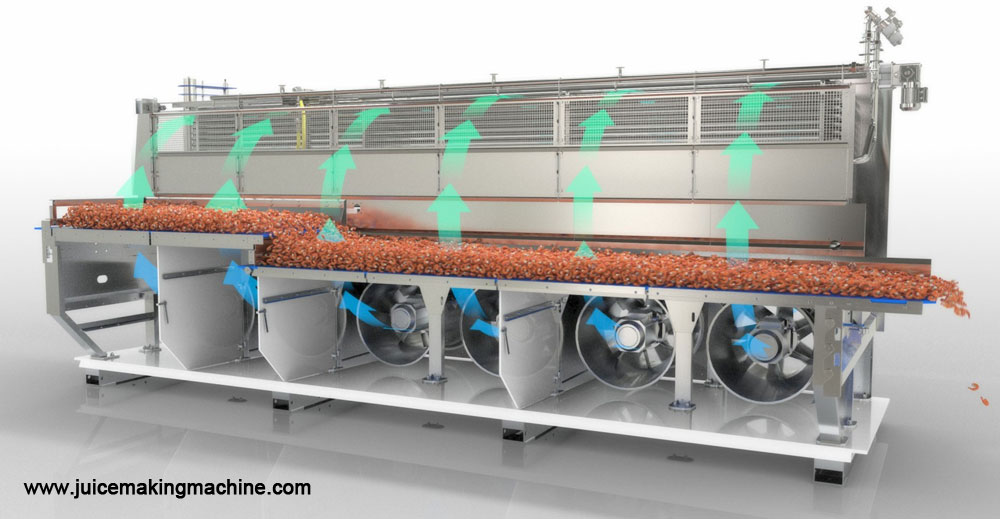

Products are evenly distributed onto a stainless steel or food-grade mesh conveyor belt and conveyed through a straight freezing tunnel. Inside the tunnel, high-velocity cold air is blown across the product surface from optimized airflow zones.

This process allows heat to be removed quickly and evenly, forming a frozen crust on each piece in a short time. As a result, products remain individually separated and retain their original shape, texture, and appearance.

The continuous design ensures stable production and easy integration into automated processing lines.

Why Choose Our IQF Tunnel Freezer?

Compared with other IQF freezing solutions, tunnel freezers offer a practical balance between capacity, cost, and operational simplicity.

-

Designed for continuous, high-volume IQF production. Reliable performance for continuous operation.

-

Excellent freezing uniformity for small and medium-sized food pieces with food grade hygienic construction.

-

Straight tunnel structure for easy access, cleaning, and maintenance.

-

Lower initial investment compared with spiral IQF systems at similar capacities.

-

Stable mechanical refrigeration system for long-term industrial operation.

-

We have extensive experience in IQF freezing solutions.

-

Customized solutions for different products.

For processors focused on efficiency, reliability, and straightforward operation, the IQF tunnel freezer remains one of the most widely adopted IQF solutions.

IQF freezing shrimp working

IQF freezing shrimp working

Request an IQF Freezing Solution

IQF Tunnel Freezer vs Spiral IQF Freezer

Both tunnel and spiral IQF freezers are used for individually quick freezing, but they serve different production conditions.

An IQF tunnel freezer is typically the better choice when products are small, free-flowing, and uniform in size, high hourly output is required, sufficient factory floor length is available and ease of operation and maintenance is a priority.

Spiral IQF freezers, on the other hand, are more suitable when factory space is limited or when longer freezing residence time is needed within a compact footprint.

Choosing the right system depends on product characteristics, production capacity, and available space.

Key Features of IQF Tunnel Freezer

-

High-velocity air circulation for rapid heat transfer.

-

Uniform freezing across the entire conveyor width.

-

Adjustable belt speed to match different products and capacities.

-

Robust insulated tunnel structure for stable low-temperature operation.

-

Hygienic design compliant with food safety standards.

-

Continuous operation suitable for 24/7 industrial production.

Each feature is engineered to ensure consistent freezing performance under demanding production conditions.

Customization and Configuration Options

Every IQF tunnel freezer can be tailored to match specific processing requirements. Configuration options include:

-

Conveyor belt width and tunnel length are adjustable according to real situation.

-

Required freezing capacity (kg/h).

-

Airflow direction and fan arrangement.

-

Refrigeration system type (ammonia or Freon-based).

-

Infeed and discharge height to match upstream and downstream equipment.

System design is always based on the product size, moisture content, inlet temperature, and target output temperature.

AGICO IQF tunnel freezer

AGICO IQF tunnel freezer

AGICO IQF tunnel freezer

Request an IQF Freezing Solution

Typical Technical Parameters

The following parameters may vary depending on product type and capacity requirements:

-

Freezing capacity: customized according to production demand.

-

Inlet product temperature: typically ambient or pre-cooled.

-

Outlet product temperature: usually −18°C or lower.

-

Conveyor belt material: stainless steel or food-grade mesh.

-

Refrigeration system: industrial mechanical refrigeration.

Detailed technical specifications are confirmed during project evaluation.

IQF tunnel freezers are commonly integrated into complete processing lines, including: washing and sorting, cutting or dicing, blanching (if required), IQF tunnel freezing, weighing and packaging.

The straight-line tunnel design allows smooth product flow and simple connection with existing equipment.

When to Choose an IQF Tunnel Freezer

An IQF tunnel freezer is recommended when:

-

You process vegetables, fruits, seafood, or diced food products.

-

High and stable production output is required.

-

Continuous operation is preferred over batch freezing.

-

Factory layout allows a straight tunnel installation.

-

Long-term reliability and easy maintenance are important factors.

If you are unsure whether a tunnel freezer or spiral freezer better fits your project, technical evaluation is strongly recommended.

Our advantages

Our advantages

Get a Customized IQF Tunnel Freezer Solution

Every freezing project is different. To ensure optimal performance, our engineers design each IQF tunnel freezer based on your actual product and production requirements.

Contact us to receive: free technical consultation, customized capacity and layout proposal and professional equipment selection support.

Tell us your product type, size, and required output, and we will recommend the most suitable IQF freezing solution for your processing line.

Technical Data

|

Model |

Power |

Dimension |

Voltage |

|

AG100 |

5KW |

5300*2500*2500mm |

380V50HZ 3phase |

|

AG200 |

8.2KW |

6700*2700*2500mm |

380V50HZ 3phase |

|

AG300 |

11.2KW |

7900*3300*2500mm |

380V50HZ 3phase |

|

AG500 |

20KW |

8200*4200*3200mm |

380V50HZ 3phase |

|

AG1500 |

50KW |

14200*4200*3300mm |

380V50HZ 3phase |

|

AG2000 |

72KW |

17700*4200*3300mm |

380V50HZ 3phase |

Get in Touch Now!

IQF tunnel freeazer application

IQF tunnel freeazer application

AGICO IQF tunnel freezer

AGICO IQF tunnel freezer AGICO IQF tunnel freezer

AGICO IQF tunnel freezer AGICO IQF tunnel freezer

AGICO IQF tunnel freezer Our advantages

Our advantages