Air Blast Tunnel Freezer

Air Blast Tunnel Freezer Introduction

The air blast tunnel freezer, also commonly referred to as a tunnel blast freezer, uses forced cold air circulation to freeze products continuously in a tunnel configuration.

An air blast tunnel freezer is a widely used industrial mechanical freezing system that freezes food products by circulating low-temperature, high-volume cold air through a continuous tunnel.

It is one of the most common and cost-effective tunnel freezer solutions in the food processing industry.

Air blast tunnel freezers are suitable for a wide range of food products and are especially popular in medium to large-scale production lines where stable performance, flexible application, and controlled investment cost are required.

Air blast tunnel freezer for freezing food

Air blast tunnel freezer for freezing food

Request a Freezing Solution

What Is Air Blast Freezing?

Air blast freezing is a mechanical freezing method that uses refrigerated air as the heat transfer medium. In an air blast tunnel freezer:

-

Cold air is generated by a mechanical refrigeration system.

-

Air is circulated at controlled speed inside the insulated tunnel.

-

Food products are exposed to continuous cold airflow.

-

Heat is gradually removed until the desired core temperature is reached.

Although the freezing speed is slower than cryogenic or impingement tunnel freezer, air blast freezing offers excellent versatility and economic efficiency.

How Does an Air Blast Tunnel Freezer Work?

In an air blast tunnel freezer, food products are evenly distributed on a stainless steel mesh conveyor belt, then the belt moves continuously through the insulated freezing tunnel. Cold air is blown horizontally or vertically across the product and heat is transferred from the product to the cold air. Finally, frozen products exit the tunnel and proceed to packaging or storage.

Multiple airflow paths and temperature zones can be arranged to ensure consistent freezing conditions across the tunnel. Freezing time is controlled by adjusting air temperature, airflow volume, and conveyor speed.

The freezer operates continuously, making it suitable for high-volume industrial production.

AGICO air blast tunnel freezer site

Air blast freezer freezing fish

Finished air blast freezer

Send Your Product Details

Key Features of Air Blast Tunnel Freezer

✔ Stable freezing performance for continuous operation

Air blast tunnel freezers are designed for steady, long-duration operation and can support multi-shift production schedules without frequent system adjustments.

✔ Suitable for a wide range of food products

The gentle freezing process makes this system suitable for products with varying shapes, sizes, and moisture content, including packaged and unpackaged foods.

✔ Mature and proven mechanical refrigeration technology

Air blast freezing systems are widely adopted in the food industry and benefit from well-established refrigeration components and control methods.

✔ Lower initial investment compared with high-speed freezing systems

Compared with impingement or cryogenic freezing systems, air blast tunnel freezers typically require lower initial equipment investment for similar production capacities.

✔ Simple system structure and easy operation

The system design focuses on reliability and ease of use, mostly with durable stainless steel structure, reducing operator training requirements and simplifying daily operation and maintenance.

Air blast freezer operation and maintenance

Air blast freezer operation and maintenance

Request Technical Details

Advantages of Air Blast Tunnel Freezer

Compared with other tunnel freezing technologies, air blast tunnel freezers offer several practical advantages:

-

Lower initial investment cost.

-

Simple system structure.

-

Easy integration into existing processing lines.

-

Flexible capacity adjustment.

-

Suitable for both new plants and production expansion.

These advantages make air blast tunnel freezers a preferred choice for standard industrial freezing applications.

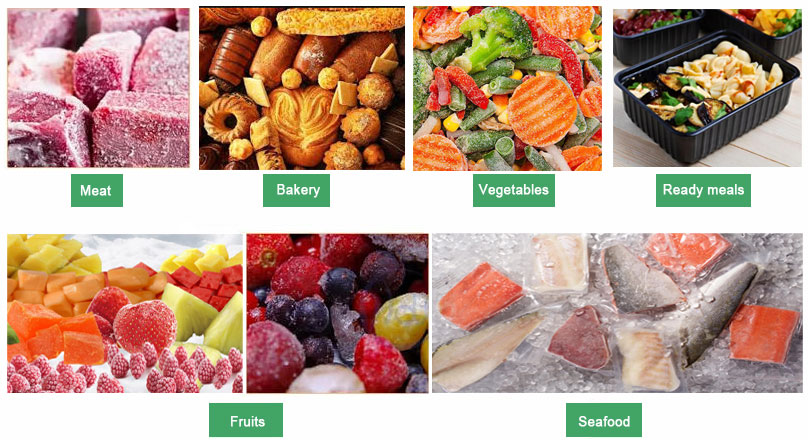

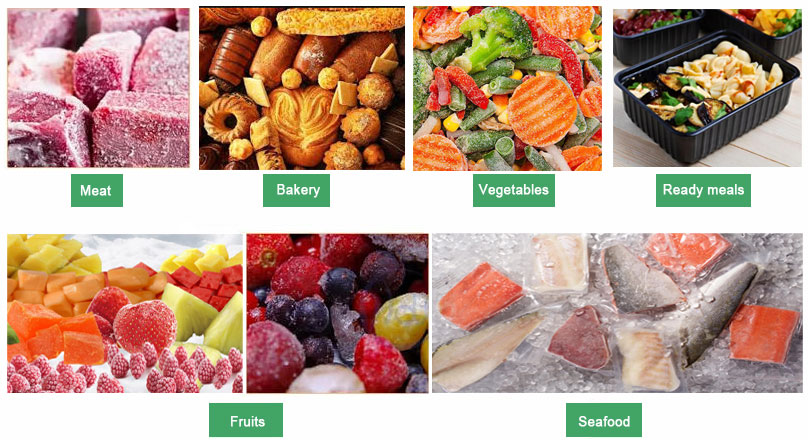

Air Blast Tunnel Freezer Applications

Air blast tunnel freezers are like other mechanical tunnel freezers, they are commonly suitable for freezing a wide variety of food products, such as fruits and vegetables, meat, poultry, seafood, bakery products, ready meals, peas, corns, and packaged foods etc.

They are particularly suitable for processors who require reliable freezing performance across a broad product range without frequent process changes.

Air blast freezer application

Air blast freezer application

Air Blast Tunnel Freezer vs Other Tunnel Freezers

When compared with liquid nitrogen tunnel freezer technologies, air blast tunnel freezer has the features of lower operating cost and slower freezing speed, so it is suitable for large-volume standard products.

While compared with impingement tunnel freezer, air blast tunnel freezer is more flexible for various product shapes and it has lower equipment complexity and lower air velocity requirements. So air blast freezer provide a balanced solution between performance and cost.

Customization Options

Our air blast tunnel freezers can be customized according to:

-

Required freezing capacity.

-

Product type and size.

-

Tunnel length and conveyor belt width.

-

Refrigeration system configuration.

-

Available factory space.

Each system is designed to integrate smoothly with existing specific production conditions like processing lines and factory layouts. For example, customers can configure freezing capacity according to the production volume, the inlet product temperature can be ambient or pre-cooled. Based on the freezing time, the tunnel length, conveyor belt width even conveyor speed can be customized and adjustable.

Air blast tunnel freezer details

Air blast tunnel freezer details

Request a Customized Solution

Why Choose Our Air Blast Tunnel Freezer?

-

Professional manufacturer of food freezing equipment.

-

Stable and proven design for long-term operation.

-

Food-grade stainless steel construction.

-

Custom engineering and layout support.

-

Reliable after-sales technical service.

-

We provide complete air blast freezing solutions for food processing plants worldwide.

Request Technical Information or Quotation

An air blast tunnel freezer is typically selected when production volumes are stable, freezing speed requirements are moderate, and long-term operational reliability is a priority.

For processors seeking a proven freezing solution with balanced investment and operating costs, air blast tunnel freezers remain a practical choice.

If you are looking for a reliable air blast tunnel freezer manufacturer, please contact us with your product details and freezing capacity requirements.

Our technical team will help you select the most suitable tunnel freezer solution.

Get in Touch Now!

Air blast tunnel freezer for freezing food

Air blast tunnel freezer for freezing food AGICO air blast tunnel freezer site

AGICO air blast tunnel freezer site Air blast freezer freezing fish

Air blast freezer freezing fish Finished air blast freezer

Finished air blast freezer Air blast freezer operation and maintenance

Air blast freezer operation and maintenance Air blast freezer application

Air blast freezer application Air blast tunnel freezer details

Air blast tunnel freezer details