Mango Pulp Machine

About Mango Pulp Machine

Mango is a very common fruit in the world, processing mango into mango pulp or mango juice is very popular. We all know that mango is the king of tropical fruits, it is extremely rich in vitamin A, with a content as high as 3.8%. Meanwhile, mango contains 14–24.8% of soluble nutrients. What’s more, mangoes are packed with various beneficial chemical elements that contribute to human health. So the mango juice production line appears as well. No matter whether to process mangoes into mango juice, mango pulp or mango jam, it is necessary to choose suitable mango processing machines.

Mango pulp machine

Send Inquiry Now!

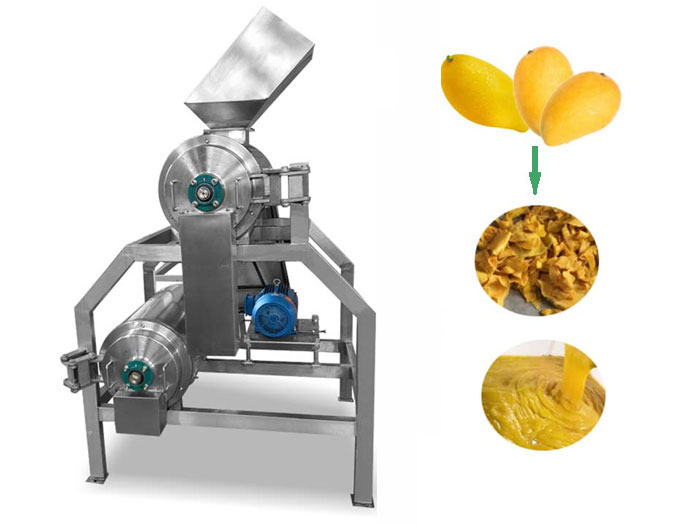

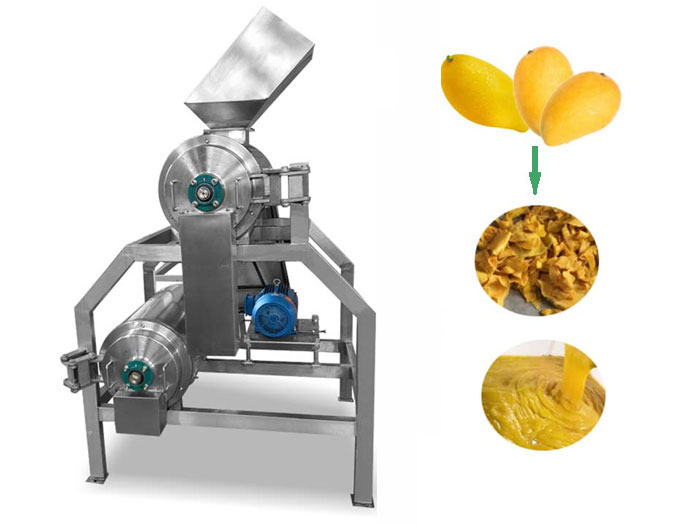

In the modern juice and pulp processing industry, the mango pulp machine is one of the most important equipment in the mango juice production line. The mango pulp machine is also known as a mango pulper or mango pulp making machine. It is mainly used to make mango pulp, while at the same time, the mango pulp machine can automatically peel and de-stone mangoes, which provides high-quality raw materials for mango juice, jam, ice cream, fruit puree beverages, and baby food.

Making mango pulper

Mango pulp making machine working

Mango pulp machine in factory

Why AGICO Mango Pulp Making Machine?

AGICO mango pulp making machine is made of 304 stainless steel, with features of compact structure, simple operation, and easy cleaning and maintenance. The mango pulp machine efficiently separates the pulp from the peel and core through the interaction between the rotating screen and the stirring blades, resulting in a fine and uniform mango pulp. It is suitable for pulping various fruits and vegetables such as fresh mangoes, peaches, papayas, tomatoes, apricots, apples, pears, strawberries, cherries, grapes, plums, kiwis, garlic, onions, jujube, etc. The produced pulp has the advantages of minimal nutrient loss, long shelf life, and excellent taste.

If you are in the mango juice processing industry, using our mango pulp machine will help you obtain high-quality mango pulp and greatly improving your production efficiency.

If you are planning to start a mango juice production business, our mango pulper offers easy operation and simple structure.

Want to extract mango juice more easily? Our mango pulp making machines are automated and specially designed for fruit processing.

Our mango pulp machine can be customized according to your required capacity. Whether you need 100 kg/h, 1 ton/h, or 2 tons/h, we can design and manufacture the most suitable mango pulping machine for you.

Mango pulper working process

Send Inquiry Now!

AGICO Mango Pulp Machine Advantages and Features

-

Single-stage or double-stage pulping design

The first stage removes the mango stone, and the second stage refines the pulp, achieving automatic separation of pulp, peel, and seed. The pulp yield can reach over 98%.

-

Vertical pulping structure

Compared with traditional horizontal mango pulp machines, the utilization rate of the screen plate is increased by 50%, and the working efficiency is also improved by 50%. It is a new generation of mango pulp making machine and one of the most practical devices in the industry.

-

Easy and safe operation

Controlled by a stable and reliable electric system, our mango pulp machine can be operated by a single worker. It is safe, convenient, and efficient, achieving fully automatic operation and reducing heavy manual labor.

-

Food-grade stainless steel construction

All parts of the mango pulper in contact with mango are made of high-quality stainless steel, meeting food hygiene and safety standards, corrosion-resistant and easy to clean.

-

Wide application range

AGICO mango pulp making machine is suitable not only for mango but also for various tropical fruits and some vegetables. Different models and configurations are available according to production capacity requirements (0.5–50 tons/hour).

-

Flexible use

The mango pulp making machine can be used as a standalone machine or integrated into a complete mango juice production line. The sieve size can be adjusted from 0.3 to 15 mm, allowing customized pulp consistency for different materials.

Mango Pulp Making Machine Working Principle

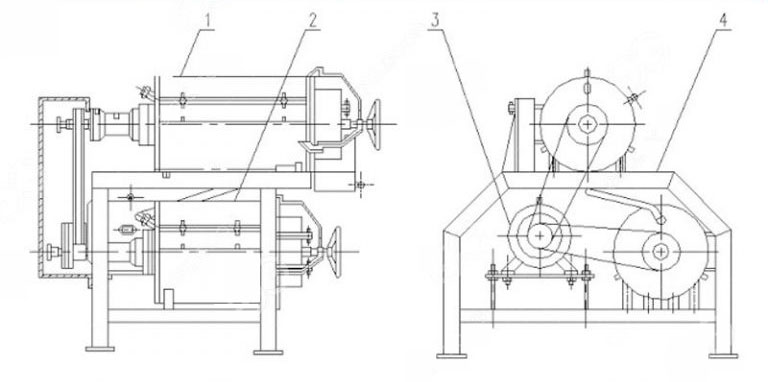

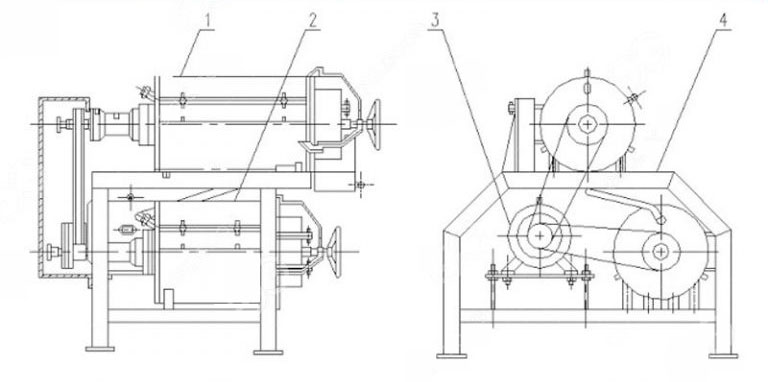

The main components of the mango pulp machine include the feeding hopper, residue outlet, juice outlet, cylinder body, sieve screen, pulping scraper, de-stoning rotor, frame, and transmission section.

1. First beater 2. Second beater 3. Motor 4. Frame

The motor provides power for the system, driving the belt to rotate the scraper at high speed. When mangoes are fed into the machine, the rotating scraper removes the mango flesh. As the scraper moves, the mango pulp is broken down and pushed toward the sieve screen. When the material passes between the scraper and the screen, it moves along a spiral path.

The centrifugal force separates the mango pulp from the peel, seed, and other residues. By replacing screens of different specifications and adjusting the lead angle of the scraper, different pulping speeds can be achieved to obtain the desired results. The mango pulp passes through the sieve holes into the next process, achieving automatic separation, while the residue outlet discharges the mango peels and seeds.

Single Drum Mango Pulper Technical Parameter

|

Model |

AGDJ1-0.12 |

AGDJ1-2.5 |

AGDJ1-4 |

|

Capacity |

100-120kg/h |

1-2.5t/h |

2-4t/h |

|

Power |

1.5KW |

4kw |

7.5kw |

|

Voltage |

380V 50HZ |

|

Raw material |

stainless steel 304 |

Double Drum Mango Pulper Technical Parameter

|

Model |

Capacity(t/h) |

Power(kw) |

Dimension(mm) |

|

AGDJ2-4 |

2-4 |

7.5 |

1510*1370*1640 |

|

AGDJ4-7.5 |

4-7.5 |

18.5 |

1980*1540*1810 |

|

AGMDJ1-2.5 |

1-2.5 |

4 |

1450*820*1580 |

|

AGMDJ2-4 |

2-4 |

7.5 |

1510*1370*1700 |

|

AGMDJ4-7.5 |

4-7.5 |

18.5 |

1930*1540*1950 |

High Speed Mango Pulper Technical Parameter

|

Capacity |

10t/h |

|

Power |

30kw |

|

Rotating speed |

970rpm |

|

Dimension |

1980*1200*2060 |

Note: We can customize various models of mango pulp machine according to customers' requirements.

Various mango pulp making machines

Mango Juice Production Line

The mango pulper is usually used together with the following equipment to form a complete mango juice or mango pulp production line.

-

Fruit Washing Machine

-

Mango Destoner

-

Mango Pulp Machine

-

Juice Filter Machine

-

Homogenizer & Sterilizer

-

Filling Machine

The entire production line features a high degree of automation, enabling continuous production from fresh mangoes to packaged juice.

The mango pulp machine is one of the core pieces of equipment in modern mango processing. AGICO can provide one-stop solutions ranging from single machines to complete mango juice production lines according to customer needs. We offer advanced technology and comprehensive after-sales service.

With mango pulper to make mangoes into pulp

If you would like to know the price of a mango pulping machine, please feel free to contact us. We are a professional mango pulping machine manufacturer. Prices of mango pulper vary depending on production capacity, generally ranging from USD 4,000 to USD 10,000. For the latest quotation or detailed information, you can leave a message or contact us online.

Get in Touch Now!