Banana Chips Slicing Machine

About Banana Chips Slicing Machine

In the banana chips processing line, the slicing stage is a critical step that determines the uniform thickness, appearance quality, and final yield of the product. A high-performance banana chips slicing machine can significantly improve production efficiency while ensuring consistent slice thickness and shape, making it an essential piece of equipment for any banana chips factory.

Send Inquiry Now!

The banana slicing machine we provide, also known as a banana chips slicer or banana chips cutting machine, is designed to quickly cut peeled bananas into uniform thin slices. In addition to bananas, this cutting machine can also be used for slicing various raw materials that need to be cut into round slices, such as apples, pineapples, lemons, potatoes, cucumbers, eggplants, onions, carrots, cassava, taro, bitter melon, lotus root, and more.

To meet different production capacities and working conditions, we offer a wide range of configurations: from small laboratory chips slicing machine to large industrial-grade cutting machines, helping customers build production lines ranging from manual operation to fully automated systems.

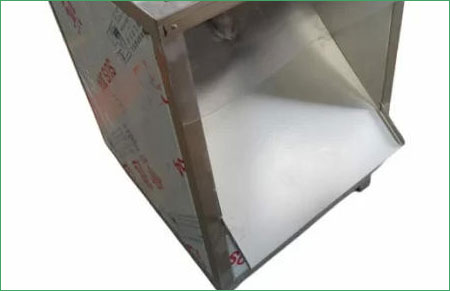

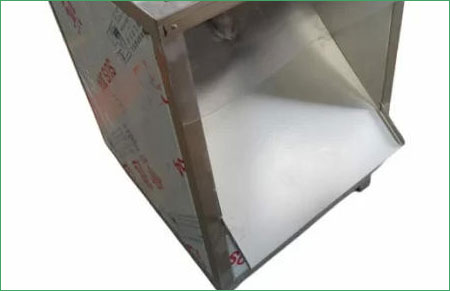

Banana chips slicing machine structure

Banana chips slicing machine structure

Send Inquiry Now!

Why Choose AGICO Banana Chips Slicing Machine?

-

Uniform Slices with Adjustable Thickness

Our professional banana chips slicing machine adopts a high-speed rotary cutting system. Slice thickness can be adjusted according to production requirements (typically 1–10 mm), ensuring smooth, uniform slices that heat evenly during frying or drying.

Banana chips

Banana chips cutting machine

Send Inquiry Now!

-

Protects the Integrity of Banana Flesh

Banana flesh is soft and easy to be deformed, making it difficult for ordinary vegetable cutters to maintain slice quality. Our banana chips slicer uses a specially designed cutting disc that slices smoothly, maximizing slice integrity without breaking, cracking, or pulling.

-

Easy to Clean & Food-Grade Standard

The cutting machine body is made of food-grade stainless steel that meets HACCP requirements. Smooth surfaces with no dead corners make cleaning quick and easy. It is suitable for bananas as well as cassava, potatoes, apples, pineapples, lotus root, and various fruits and root vegetables.

Banana chips slicing machine blades

Banana chips slicer inlet

Banana chips cutting machine outlet

Send Inquiry Now!

Banana Chips Slicer Technical Parameter

|

Product name |

Banana chips slicer |

|

Capacity |

200-800kg/h |

|

Power |

0.75kw |

|

Voltage |

380v |

|

Dimension |

650*550*900mm |

|

Banana chips thickness |

1.8mm-8mm |

Features of Banana Chips Slicing Machine

-

There are three blades on the banana chips slicing machine. The blades are made of steel of 404C. The cutter frame is made of aluminum alloy, which ensures a long lifespan.

-

Customers can customize the slicing inlet hole quantity such as 4 holes, 5 holes and 6 holes, slicing inlet size and cutting angle according to the capacity to get different banana chips thickness.

-

It is easy to operate and maintain the banana chips slicer with high capacity and stable performance.

-

It is suitable for various fruits and vegetables, such as apples, potatoes, cucumbers, eggplants and so on.

Different feeding holes of banana chips slicer

Different feeding holes of banana chips slicer

Banana chips machine applications

Banana chips machine applications

Send Inquiry Now!

Banana Chips Slicing Machine Working Principle

The working principle of a banana chips slicing machine is designed to ensure fast slicing, uniform thickness, and minimal damage to the soft banana flesh. Although the structure is simple, the slicing machine integrates several food-processing optimizations to achieve stable and high-quality slicing results.

1. Feeding System

After peeling with banana peeling machine, bananas are manually placed into the feeding slot or delivered through an automatic conveyor.

The feeding chute is typically curved or guided to protect the soft banana flesh from deformation before entering the cutting zone.

2. Positioning and Guiding Mechanism

Once inside the feeding inlet, the bananas are slightly fixed and guided into the correct position.

This mechanism is essential to prevent the banana from slipping, maintain consistent slice thickness and ensure stable and uniform slicing. Depending on the model of banana chips slicer, guiding structures can be curved channels, pressure plates, or roller guides.

3. High-Speed Rotary Cutting Disc

The core component of the banana chips slicing machine is the high-speed rotating cutting disc. After feeding bananas into the cutting area, the motor drives the cutting disc at high speed, then the blades rapidly slice the bananas into thin, uniform pieces, finally finished slices fall naturally into the collection tray or conveyor. Different blade types (straight, curved, serrated) can be used depending on the slicing requirements.

4. Adjustable Slice Thickness

Most banana chips slicers allow slice thickness adjustment, typically in the range of 1–10 mm.

Through hand-wheel micro-adjustment, blade angle adjustment or distance adjustment between disc and guide plate, the thickness adjustment can be achieved.

5. Automatic Discharge

After slicing, the banana chips are discharged through gravity, airflow assistance, or a conveyor belt. The slices then move to the following processes such as blanching, dehydration, frying, drying, or seasoning.

Banana chips cutting machine in factory

Banana chips slicer application

Send Inquiry Now!

Contact Us for Free Quote

No matter you are looking for banana chips slicing machine, banana chips slicer, or banana chips cutting machine, AGICO can offer high quality and professional banana chips processing solution. We can customize the blades materials, different thickness of slices, production capacity and automation of banana chips slicing machine according to your requirements. If you are interested in banana processing, please contact us now to get the consultation and free quote. We will waiting for you at any time!

Get in Touch Now!

Banana chips slicing machine structure

Banana chips slicing machine structure Banana chips

Banana chips Banana chips cutting machine

Banana chips cutting machine Banana chips slicing machine blades

Banana chips slicing machine blades Banana chips slicer inlet

Banana chips slicer inlet Banana chips cutting machine outlet

Banana chips cutting machine outlet Different feeding holes of banana chips slicer

Different feeding holes of banana chips slicer Banana chips machine applications

Banana chips machine applications Banana chips cutting machine in factory

Banana chips cutting machine in factory Banana chips slicer application

Banana chips slicer application