Heat Shrink Wrapper

Heat Shrink Packing Machine Introduction

The heat shrink packaging machine, also known as heat shrink packing machine, heat shrink wrapper machine, automatic heat shrink machine etc, is a high-efficiency, continuous operation packaging equipment designed and manufactured according to the characteristic of packaging film shrinking when heated.

It can automatically arrange and assemble individual PET beverage bottles or similar items such as cans, or carton boxes etc, into groups, then wrap them with heat shrink film, and finally form collective packaging through heating shrinkage and cooling shaping.

The packaged products are firmly bound with a regular and beautiful appearance and is easy to open. Therefore, it is widely applied in industries such as beverage, food, medicine, chemicals, printing and other light industrial products to create a tight and durable outer film package that protects the products and improves their appearance.

Heat shrink wrapping packaging machine application

Send Inquiry Now!

Types of Heat Shrink Packaging Machine

There are many types of heat shrink wrapping or packing machines. Internationally, the heat shrink packing machine is generally classified into L-shaped shrink wrapping machines, linear shrink wrapping machines and one-piece shrink wrapping machines according to different packaging forms. In addition, depending on the application, film raw materials and degree of automation of the heat shrink packaging machine, it can also be classified differently. In this text, we mainly introduce our linear shrink packing machine, and as for the L-type shrink wrapping and one-piece shrink wrapping machine, please look here.

Small linear shrink packaging machine

Large linear heat shrink packaging machine

Linear Shrink Packaging Machine

There are mainly two types of linear heat shrink packaging machine in AGICO, one is large linear shrink packing machine, the other is small linear shrink packaging machine. Our linear heat shrink wrapping machines are available in two models: AGICO-15 and AGICO-20.

Large linear shrink packing machine

The small linear heat shrink wrapper (AGICO-15) is suitable for products with a maximum package size of 425 × 280 × 330 mm, with a steady output of 0–14 packs per minute. The overall machine dimensions are 9600 × 1200 × 2200 mm.

The large linear shrink wrapping machine (AGICO-20) is designed for products with a maximum package size of 425 × 280 × 330 mm, with a steady output of 0–19 packs per minute. The overall machine dimensions are 13800 × 1600 × 2200 mm.

According to the customer’s bottle shape and package dimensions, the linear heat shrink packaging machine can be customized to meet different production requirements.

Features and Advantages of AGICO Linear Shrink Packaging Machine

-

The linear shrink wrapping machine adopts an advanced heat sealing and cutting structure, ensuring firm sealing, neat edges, and excellent seam performance.

-

The sealing mechanism is driven by a cylinder with guide pillars at both ends, ensuring smooth and reliable film cutting and sealing.

-

The small linear shrink packing machine uses a flat plate conveying system, achieving stable product delivery without changing templates. It can adapt to various bottle shapes and is easy to operate. The large linear shrink packaging machine adopts a ribbed panel conveyor, preventing bottles from toppling even at high production speeds.

Send Inquiry Now!

Advanced heat sealing and cutting structure

Constant temperature heat shrink tunnel

-

Our linear shrink packaging machine is equipped with a PID temperature controller, providing accurate and energy-saving temperature control. The sealing and shrinking temperatures are automatically regulated and can be adjusted as needed.

-

The heat shrink tunnel features an advanced spiral air circulation structure and three-layer thermal insulation, providing high energy efficiency.

Send Inquiry Now!

-

The bottle feeding system of linear shrink packing machine uses imported high-speed fiber optic sensors for counting, ensuring precise and stable operation. An intelligent monitoring system is added—when bottles fall over accidentally, the heat shrink packaging machine will automatically detect the issue, stop conveying, and sound an alarm. Once the problem is cleared, simply press “Cancel Alarm” on the control panel to resume operation.

-

The touch screen control system of our linear shrink packaging machine allows for high-precision and intelligent motion control. All machine actions, alarms, and PLC statuses are displayed on the screen for safer and more reliable operation. AGICO linear shrink packing machine also supports single-step manual operation, making debugging and maintenance easier.

Linear Shrink Packaging Machine Details

Uniform key slot adjustment package for bottle sides

New design of large linear shrink packaging machine

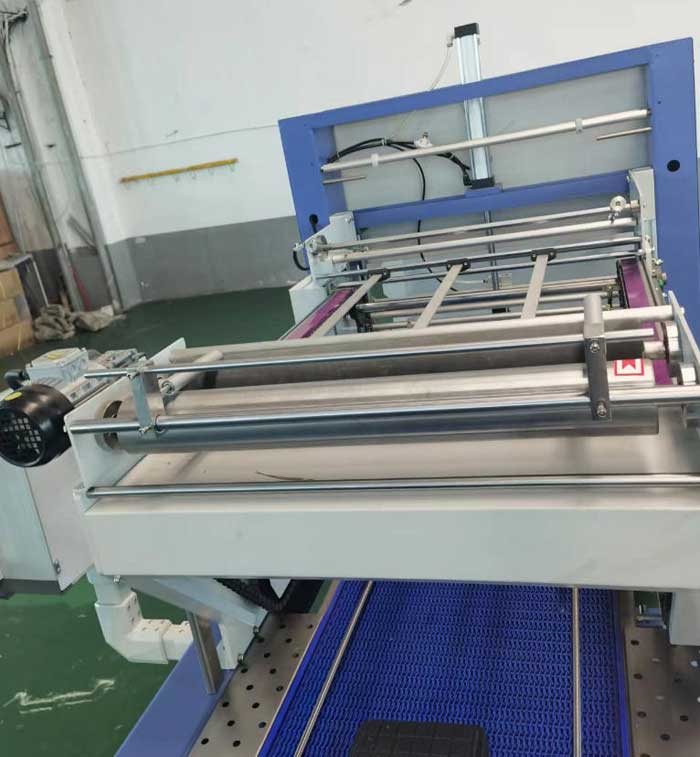

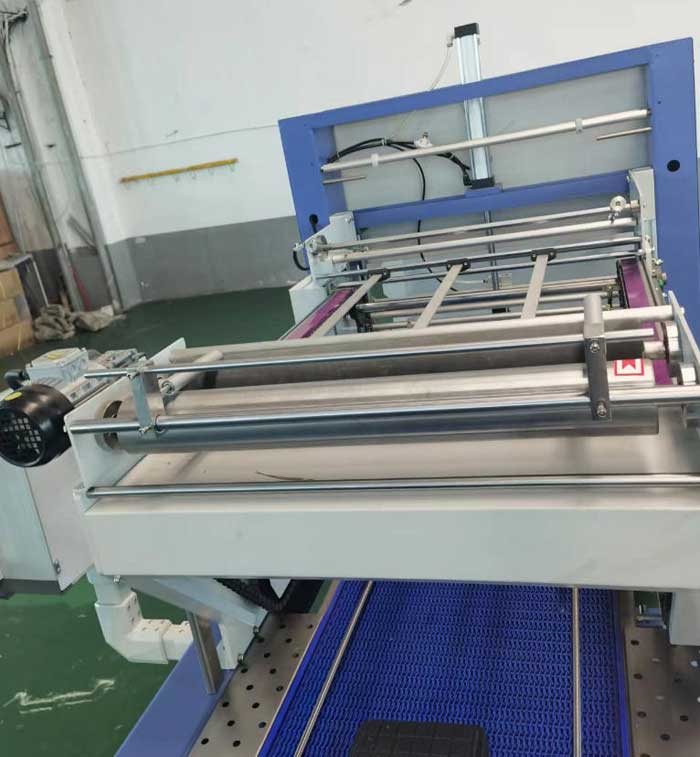

Linear shrink packaging machine with lever conveyor

Delivery of film for linear shrink packing machine

Linear shrink packing machine details

Heat shrink wrapper pressing section can be adjusted up and down

Delivery of film for linear shrink packing machine

Bottle divider adjustment button of linear shrink packing machine

Chain conveyor gate of large linear shrink packaging machine

-

The linear shrink wrapping machine is equipped with an automatic alarm system to further enhance safety and reliability. The automatic control system enables automatic feeding, bottle sorting, film shrinking, and cooling, suitable for continuous long-term operation without stopping.

-

The heat shrink tunnel features an advanced spiral air circulation structure and three-layer thermal insulation, providing high energy efficiency.

-

The conveying height, feed direction, and machine dimensions of heat shrink packaging machine can all be customized according to customer requirements.

-

Trayless packaging design makes our linear shrink packaging machine easy to adjust for different bottle sizes and combinations, preventing bottles from slipping or toppling.

-

The large linear heat shrink wrapper uses a chain pusher system that smoothly guides bottles into the guard rails without scratching the bottle surface.

Working Process of Linear Shrink Packaging Machine

Product conveying → Product sorting → Film wrapping → Film unwinding → Bottle pressing

↓

Finished product output ← Cooling & shaping ← Heat shrinking ← Sealing & cutting ←

Large Linear Shrink Packaging Machine Technical Parameter

|

Model |

AG-MB-20 |

|

Packaging Specification |

2*3,3*4,3*5,4*6 |

|

Overall Dimensions |

L13140*W1100*H2150 mm |

|

Hear Shrink Furnace Size |

L4000*W100*H2000 mm |

|

Packaging Speed |

16-20pc/m |

|

Sealing and Cutting Time |

0.5-1.2s |

|

Sealing and Cutting Temperature |

160-200℃ |

|

Voltage |

380V/50HZ |

|

Power |

28kw |

|

Air Pressure |

0.6-0.8Mpa |

|

Air Flow Rate |

0.5m³/Min |

|

Weight |

1500kg |

Small Linear Shrink Packaging Machine Technical Parameter

|

Model |

AG-MB-15 |

|

Packaging Specification |

2*3,3*4,3*5,4*6 |

|

Overall Dimensions |

L9841*W1000*H2000 mm |

|

Hear Shrink Furnace Size |

L3700*W92*H2000 mm |

|

Packaging Speed |

9-15pc/m |

|

Sealing and Cutting Time |

0.5-1.5s |

|

Sealing and Cutting Temperature |

160-180℃ |

|

Voltage |

380V/50HZ |

|

Power |

23kw |

|

Air Pressure |

0.6-0.8Mpa |

|

Air Flow Rate |

0.3m³/Min |

|

Weight |

1200kg |

Get in Touch Now!

Advanced heat sealing and cutting structure

Advanced heat sealing and cutting structure Constant temperature heat shrink tunnel

Constant temperature heat shrink tunnel Uniform key slot adjustment package for bottle sides

Uniform key slot adjustment package for bottle sides New design of large linear shrink packaging machine

New design of large linear shrink packaging machine Linear shrink packaging machine with lever conveyor

Linear shrink packaging machine with lever conveyor Delivery of film for linear shrink packing machine

Delivery of film for linear shrink packing machine Linear shrink packing machine details

Linear shrink packing machine details Heat shrink wrapper pressing section can be adjusted up and down

Heat shrink wrapper pressing section can be adjusted up and down  Delivery of film for linear shrink packing machine

Delivery of film for linear shrink packing machine Bottle divider adjustment button of linear shrink packing machine

Bottle divider adjustment button of linear shrink packing machine Chain conveyor gate of large linear shrink packaging machine

Chain conveyor gate of large linear shrink packaging machine