Batch Fryer Machine

Batch Fryer Introduction

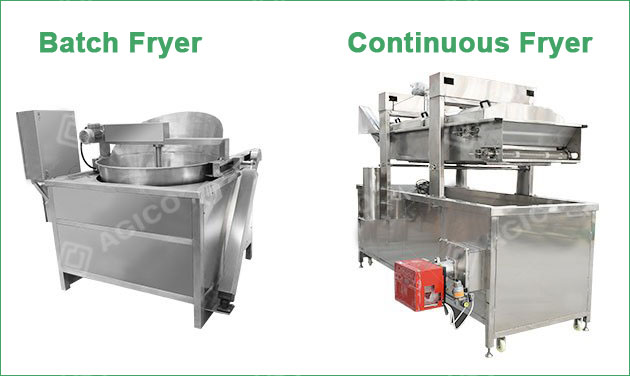

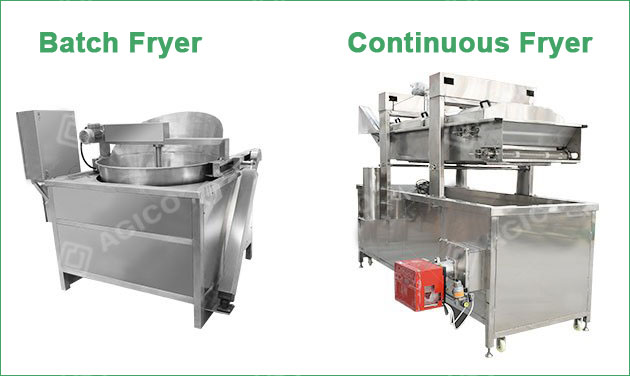

Batch fryer works by frying food in batches. The food to be fried is placed into the frying tank of the batch fryer machine, cooked for a set period, and then discharged manually or automatically. After one batch is finished, the next batch of food is loaded for frying.

This batch-cycling operation makes the batch fryer machine an ideal frying solution for small and medium-scale food production. It is commonly used in small potato chip factories, restaurants, and laboratories to process snacks such as potato chips, peanuts, banana chips, onion rings, and other fried foods.

Compared with continuous fryer machines, the batch fryer machine has features such as lower cost, simple operation, flexible heating methods, and adjustable frying time and temperature etc.

Electric heating batch fryer machine

Send Inquiry Now!

Why Choose AGICO Batch Fryer Machine?

-

We offer batch fryer machines with various heating methods. Whether it's an electric heating batch fryer, a gas heating batch fryer, or a diesel heating batch fryer, we can customize them according to your needs.

-

AGICO has over 20 years of experience in food machinery manufacturing and provides one-stop services from scheme design, installation and commissioning to after-sales maintenance.

-

Our batch fryer machines have various production capacities, ranging from 30kg to 600kg. We support customizing batch fryer machine process based on production capacity and process.

-

AGICO batch fryer uses high-quality stainless steel that comply with food safety requirements. It supports precise adjustment of oil temperature and frying time to ensure that the color and taste of the products are not greatly affected.

-

The batch fryer machine operation is simple, cleaning is convenient, which effectively extends the service life of the oil and improves product quality while reducing operating costs.

-

One Batch Fryer can handle various types of food easily, such as french fries, fried chicken, onion rings, spring rolls, etc. Just change the frying baskets and adjust the time/temperature between different batches.

Batch fryer applications

Models of Batch Fryer Machine

Automatic Round Batch Fryer Machine

AGICO offers round batch fryer for small and medium food processing enterprises. The round batch fryer machine is mainly composed of an inner screen frame, a stirring system, a pot body and a lifting and turning system, which can realize automatic stirring and turning, saving labor, and can be used for frying fruits and vegetables, nuts, noodles, meat, etc., there are two types of heating methods, electric heating batch fryer and gas heating batch fryer.

Gas heating round batch fryer machine

Electric heating round batch fryer machine

Automatic Round Batch Fryer Advantages

-

According to different materials, there are oil-water separation system and pure oil system technology options. The leading purification oi residue technology can extend the oil life and reduce the oil cost.

-

The round pot can realize automatic feeding, stirring, turning and discharging, improving the quality of frying and reducing labor intensity. Electricity saving is 40%, oil saving is 50%.

-

The batch fryer is heated by imported heating pipes or burners, with fast heating, good stability, energy saving and environmental protection.

-

Intelligent temperature control technology(0-300℃) improves heating efficiency and guarantees frying quality.

-

The whole machine is made of high-quality SUS304 stainless steel.

-

Automatic mixing, ensure products are uniformly fried and prevents them from compression and adhesion.

-

According to different products and requirements, this round pot batch fryer has optional timer and alarm to remind you when the frying is finished and optional slag scrapping device if the fried products produce much slag and residue.

Burner for gas heating batch fryer

Control panel for electric heating batch fryer

Oil discharging port and observation window

Discharging motor of automatic batch fryer

Batch fryer stirring motor

Stirring system and stainless mesh

Electric Heating Round Pot Batch Fryer

|

Model |

Power |

Capacity |

Weight |

Dimension (mm) |

|

AGE-1000 |

36 kw |

100 kg/h |

300 kg |

1400*1200*1600 |

|

AGE-1200 |

48 kw |

150 kg/h |

400 kg |

1600*1300*1650 |

|

AGE-1500 |

60 kw |

200 kg/h |

500 kg |

1900*1600*1700 |

Gas Heating Round Pot Batch Fryer

|

Model |

Burner |

Capacity |

Weight |

Dimension (mm) |

|

AGG-1000 |

150,000 Kcal |

100 kg/h |

600 kg |

1700*1600*1600 |

|

AGG-1200 |

200,000 Kcal |

150 kg/h |

700 kg |

1900*1700*1660 |

|

AGG-1500 |

300,000 Kcal |

200 kg/h |

900 kg |

2200*2000*1700 |

Semi-Automatic and Manual Rectangle Batch Fryer

The semi automatic and manual rectangle batch fryer isn’t like round pot batch fryer, the frying pot of the semi automatic or manual batch fryer machine is rectangle shape. The frame batch fryer has four types: single basket, two baskets, three baskets, and four baskets which customer can choose according to different production requirements. The structure is simple and the operation is convenient. It is widely used for frying chips, meat-pie, chicken nuggets, potato chips, spring rolls, peanuts, crisps, sweet potato chips, cashew, seafood, and all the other food or snacks which need frying. It is suitable for small or medium food processing industries. This semi-automatic rectangle batch fryer can equipped with automatic discharging device or just by manual to collect the final frying food. You can customize rectangle batch fryer according to your real situation.

Gas heating rectangle batch fryer machine

Electric heating rectangle batch fryer machine

Semi-Automatic Rectangle Batch Fryer Advantages

-

Using PID precise temperature control technology to improve heat efficiency and ensure the quality of frying.

-

The whole machine is simple in structure, easy to use and operate.

-

Imported brand heating system, high heating efficiency, fast heating, energy saving.

-

The whole machine is made of food grade SUS304 material, with great processing technology and stable structure.

-

There are also electric heating batch fryer and gas heating batch fryer for customers.

Basket for batch fryer

Heating tube for electric heating batch fryer

Moveable wheel

Electric Heating Batch Fryer with Automatic Discharging Device

|

Model |

Power |

Oil capacity |

Inner Size |

|

AGSE-1000 |

40 kw |

300L |

1000*800mm |

|

AGSE-1200 |

60 kw |

500L |

1500*800mm |

|

AGSE-1500 |

90 kw |

800L |

2000*800mm |

Gas Heating Rectanlge Batch Fryer with Automatic Discharging Device

|

Model |

Burner |

Oil capacity |

Inner Size |

|

AGSG-1000 |

100,000 Kcal |

500L |

1000*800mm |

|

AGSG-1200 |

200,000 Kcal |

800L |

1500*800mm |

|

AGSG-1500 |

200,000 Kcal |

1200L |

2000*800mm |

Rectangle batch fryer | semi-automatic or manual operation

Affecting Factors of Batch Fryer Machine Price

Production Capacity and Size

Frying basket capacity or oil tank capacity is the primary factor determining the batch fryer machine price. The price range for small manual batch fryers is $1,000 - $10,000, while large continuous fryers can cost up to $15,000 - $25,000. Please choose the appropriate size based on your average daily sales volume.

Heating methods

Electric heating is the most common, with convenient installation, precise temperature control, and relatively stable initial cost and operating cost.

Gas heating has a faster heating speed and may have lower operating costs (depending on the local gas price), but it requires connection to a gas pipeline and has higher installation requirements. Generally, gas batch fryer are more expensive than electric fryers of the same specification.

Automation and intelligence level

Manual batch fryers are the most economical because the time and temperature are controlled by manual.

Fully automatic batch fryers are equipped with digital PID temperature controllers, multi-stage programming functions, and automatic basket lifting. With just one button, you can complete complex oil frying processes. They are more expensive, but they can significantly improve efficiency and quality stability.

Material and Construction Technology

Batch fryer which is made of 304 food-grade stainless steel is more corrosion-resistant, easier to clean, has a longer service life, and costs more compared to 430 stainless steel.

How to Choose the Right Batch Fryer?

Before evaluating the price of a batch fryer machine, please select the most suitable one for yourself based on these questions.

-

What is my main menu? (Decide on the requirements for the equipment's functions).

-

What is my estimated sales volume during peak hours? (Decide on the required capacity and power of the batch fryer machine).

-

How is my kitchen space and energy interface? (Decide whether to choose an electric heating or gas heating batch fryer, and the size of the fryer machine).

-

What is my budget? (Search for the most cost-effective model within the budget).

Get in Touch Now!

Gas heating round batch fryer machine

Gas heating round batch fryer machine Electric heating round batch fryer machine

Electric heating round batch fryer machine

Gas heating rectangle batch fryer machine

Gas heating rectangle batch fryer machine Electric heating rectangle batch fryer machine

Electric heating rectangle batch fryer machine