Jam Processing Equipment

Complete Jam Processing Equipment for Strawberry, Blueberry and Berry Jam

Our complete jam processing equipment is specially designed for the industrial production of high-quality fruit jam. We offer each jam making equipment from washing and grading raw materials to crushing, concentration, sterilization, and final filling and packing of berry jam with customized service and factory price, welcome customers to contact us for the latest quote of jam processing equipment.

Jam making equipment for blueberry, strawberry and so on

Send Inquiry Now!

The berry fruit jam production line is widely used for strawberry jam, blueberry jam, raspberry jam and mixed berry jam etc., delivering stable performance, consistent product quality and high production efficiency.

From raw material handling to final filling and packaging, we provide a turnkey fruit jam production line that meets the requirements of food factories, beverage plants and fruit processing enterprises. Our jam making equipment can be customized according to your requirements. Each jam processing equipment has its technical requirements to meet the real situation. Just like our tomato paste production line, we offer high quality jam making equipment to help food plants, jam factories, and beverage industries to choose the most suitable equipment for berry jam.

Main jam processing equipment

Send Inquiry Now!

Jam Making Equipment Application

Berries such as strawberries, blueberries and raspberries are widely used in the production of jams, fruit sauces and beverage bases due to their rich flavor, natural color and high nutritional value.

Our turnkey jam making equipment is not only suitable for producing strawberry jam, blueberry jam, raspberry jam, blackberry jam, cranberry jam, mulberry jam, gooseberry jam, and currant jam, but also for some other soft fruit jams and fruit sauces. The jam processing equipment is widely applied in the jam and preserves factories, beverage and dairy plants, bakery filling, topping production and fruit deep processing projects.

Main jam making equipment

Send Inquiry Now!

Advantages and Features of Jam Making Equipment

-

The production line features a flexible configuration, allowing equipment with different functions to be selected and combined according to the specific requirements of customers’ final jam products.

-

With a high level of automation, the system significantly reduces labor costs. Continuous production shortens the overall processing cycle, enabling manufacturers to respond quickly to market demand.

-

The berry jam making equipment is equipped with a PLC control system that supports automatic cleaning, precise temperature control, and adjustable concentration time, effectively minimizing manual intervention and operational errors.

-

All product-contact parts are manufactured from food-grade SUS304 stainless steel, with SUS316 available as an option, fully complying with food hygiene and safety standards.

-

All jam making equipment is designed and manufactured in accordance with international food safety requirements and is certified with CE, ISO, and SGS.

-

AGICO provides fully customized berry processing equipment solutions. Backed by experienced engineers and skilled technicians, we are able to design and manufacture complete berry processing plants based on customers’ specific capacity requirements, product specifications, samples, layouts, or technical drawings.

-

The combination of vacuum concentration and temperature-controlled sterilization effectively reduces energy consumption while preserving the natural color, flavor, and nutritional value of berry jam. The berry jam production line can be easily adapted to process a wide range of jam products, including blueberry jam, strawberry jam, and raspberry jam, helping customers diversify and expand their product portfolio.

-

We offer comprehensive services covering installation and commissioning, operator training, recipe optimization, and long-term maintenance support to ensure stable, efficient, and reliable production.

Berry jam

With its advanced automation, strict hygiene design, and flexible adaptability, our berry jam making equipment delivers consistent, safe, and high-quality jam products while providing multiple configuration options to meet different production needs. If you are interested in establishing or expanding your berry jam processing business, please feel free to contact us for more information.

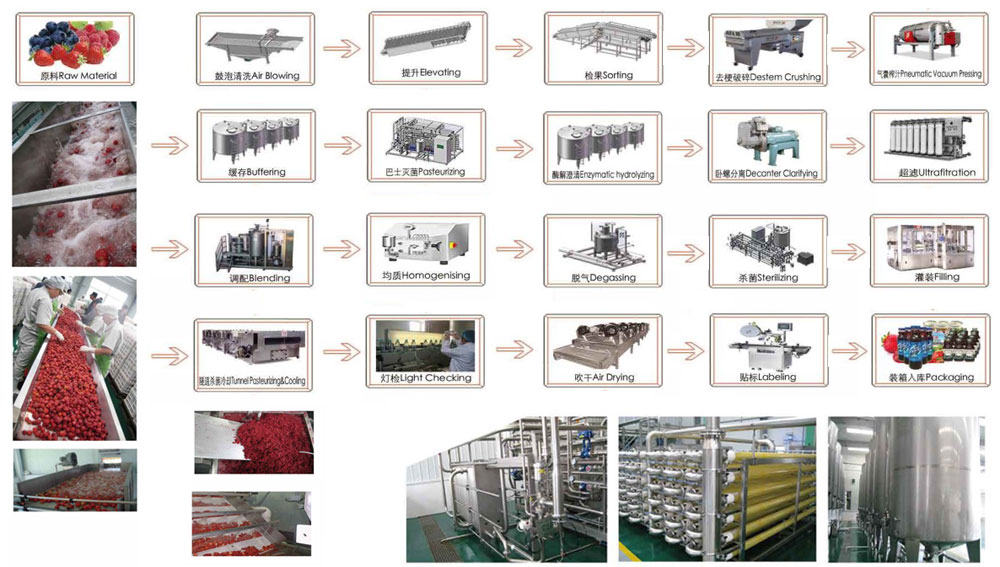

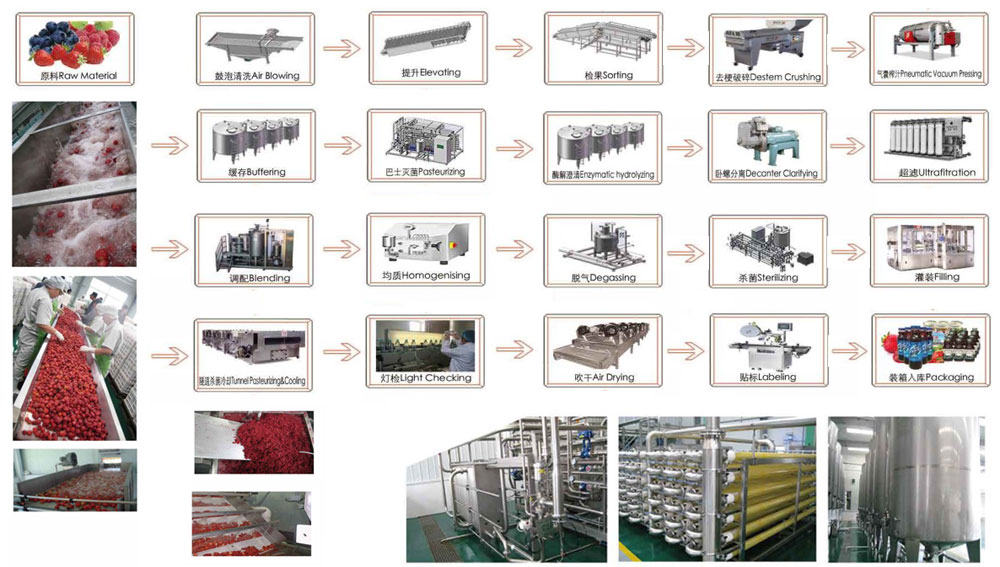

Main Equipment and Procedures of Jam Processing

We provide a full set of jam making equipment from washing to filling. Our main machines included in the jam making equipment are bubble type washing machine, sorting machine, crusher & fruit pulper, vacuum evaporator, jam cooking kettle or vacuum concentrator, mixing tank & deaerator, jam filling & packaging machine. All jam making equipment can be customized according to requirments. Generally speaking, the main production process of jam making is raw material → washing → pulping → cooking → filling.

Jam making equipment turnkey solution

Send Inquiry Now!

Fruit Washing Machine

After selecting raw materials via sorting machine, to wash them with the

fruit and vegetable washing machine is necessary. Our bubble type washing machine is widely used to clean fruits and vegetables like blueberry, strawberry, mulberry, spinach, cabbage, lettuce, pepper, chives, carrots, potatoes, sweet potatoes, apples, pears, begonia, fish, shrimp, etc, with stainless steel design and the mesh belt is used for transmission. What's more, we offer roller and spray type washing machine.

Fruit Crusher and Pulper Machine

The fruit crusher is used to carry out preliminary crushing of fruits, breaking down the fruit structure and facilitating subsequent pulping. The

pulper further processes the crushed fruit into fruit pulp and is a crucial core piece of equipment in the front section of a jam processing line. It can be configured with single-stage or double-stage pulping systems according to production requirements, features adjustable screen sizes, and is especially suitable for processing soft berries such as strawberries and blueberries. Colloid mill is the most common grinder machine in the jam processing equipment.

Jam Cooking Kettle and Vacuum Concentrator

The jam cooking kettle or cooking pot is used for heating and cooking fruit pulp together with sugar, pectin, and other ingredients. It features uniform heating, automatic stirring, and precise temperature control. The vacuum concentrator performs concentration under low-temperature conditions, which helps reduce nutrient loss, preserve natural color and flavor, and lower energy consumption, making it an essential piece of equipment among jam making equipment for producing high-quality jam.

Sterilization System

Depending on the processing requirements,

pasteurization, tubular sterilization, or tunnel sterilization systems can be selected to ensure that the jam meets food safety standards.all the sterilization system is used for the sterilizing of tomato paste, onion paste,chili paste, strawberry paste, blueberry jam, blackberry paste, carrot jam, peach paste, apricot paste etc.

Jam Filling Equipment

We offer various types of jam filling machine with different packing aims, no matter you want to filling jam into bottles or bags, we have the corresponding filling system.

Besides the above jam making equipment, there are some optional jam processing equipment according to your requirements and production capacity, such as CIP cleaning system, deaerator, mixing tank etc. If you have needs, we can customize the most suitable jam processing equipment for your industry.

Jam making equipment projects

Get in Touch Now!