Tunnel Freezer

What is a Tunnel Freezer?

A tunnel freezer is a type of continuous quick-freezing equipment. It is widely used for large-scale quick freezing of seafood, meat, poultry, fruits, vegetables, and pastry products. The products enter the tunnel through a conveyor belt and are rapidly frozen under the action of low-temperature, high-velocity cold air. Tunnel freezers are characterized by large capacity, strong continuity, high freezing efficiency, suitability for mass continuous production, and excellent frozen product quality.

An IQF freezing machine emphasizes individual quick freezing, which is mainly applied to fruits, vegetables, and seafood. It is suitable for granular, sliced, or small-sized foods (such as blueberries, strawberries, peas, shrimp, fish fillets, etc.), ensuring that each piece is frozen separately without sticking together. IQF freezing machine is essentially a process feature. In fact, IQF freezing machines are often designed with a tunnel structure.

Therefore, if your requirement is to freeze granular or small-sized products, an IQF tunnel freezer is usually the preferred choice. AGICO can customize various food freezers to meet your specific needs.

Send Inquiry Now!

Advantages of AGICO Tunnel Freezer for Sale

-

High Freezing Capacity –Designed for mass continuous production, ideal for food factories requiring 24/7 operation.

-

Energy Efficient – Optimized airflow design reduces energy consumption. Large aluminum alloy evaporator with variable fin pitch extends defrosting intervals.

-

Superior Freezing Quality – Ensures rapid freezing, keeping the original taste, texture, and nutrition of food products.

-

Versatility – Suitable for freezing granular, sliced, or large-sized food products such as meat, seafood, fruits, vegetables, and bakery items.

-

Advanced Structural Design

-

Stainless steel fans ensure rated air volume and pressure.

-

Feeding section equipped with belt cleaning and drying device.

-

All internal components are made of stainless steel for easy cleaning and maintenance.

-

Fully Automatic Control System – Equipped with advanced automation and frequency conversion technology, allowing stepless adjustment of conveyor belt speed for flexible production.

-

Ultra-Low Temperature Freezing – Can reach as low as –80ºC, suitable for deep freezing of special food products.

-

Low Power Consumption – Energy-saving operation while maintaining high freezing efficiency.

-

Customized Solutions – Different models, lengths, and features can be tailored to meet specific customer needs.

-

Flexible Belt Design – Options available for mesh belts or stainless steel belts depending on product type.

AGICO tunnel freezer in the factory

Final tunnel freezer for sale

Tunnel freezing machine for sale

Tunnel freezer for sale working

Get Tunnel Freezer Today!

Tunnel Freezer Classification

A tunnel freezer is a high-efficiency quick freezing machine with simple structure and reliable performance. According to the conveying system and freezing principle, tunnel freezers can be divided into belt tunnel freezer, plate tunnel freezer, fluidized tunnel freezer, and spiral tunnel freezer.

If you are searching for a tunnel freezer for sale at a reasonable tunnel freezer price, choosing the right type depends on your food products, production capacity, and available plant space. AGICO offers a full range of stainless steel belt tunnel freezers, mesh belt tunnel freezers, spiral tunnel freezers, and fluidized tunnel freezers, ensuring you find the most suitable solution for your business.

Belt Tunnel Freezer

The belt tunnel freezer uses stainless steel mesh belts or plastic chain belts to transport food.

✔ Suitable for block, strip, and granular foods.

✔ Commonly used for quick freezing dumplings, vegetables, fruits, and sliced meat.

Plate Tunnel Freezer

The plate tunnel freezer adopts metal plates for contact conduction freezing.

✔ Ensures even thickness and shape retention.

✔ Ideal for fish fillets, shrimp, and meat blocks.

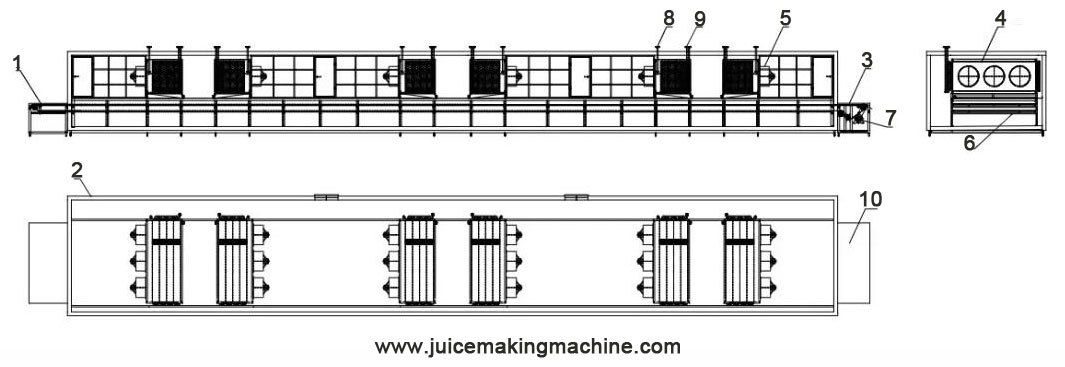

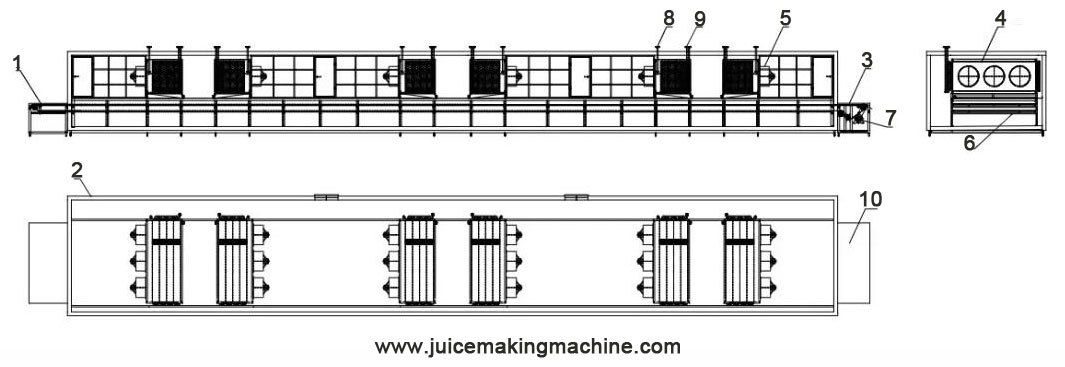

1. Feeding rack 2. Insulation storage body 3.Outlet 4.Evaporator 5. Circulating fan 6. Stainless steel footing frame 7.Transmission motor 8. Liquid supply pipe 9. Air return pipe 10.Mesh belt/plate belt

Get Tunnel Freezer Today!

Fluidized Tunnel Freezer

The fluidized tunnel freezer uses powerful cold airflow to suspend and rapidly freeze small granular foods.

✔ Especially suitable for corn kernels, peas, blueberries, and shrimp.

✔ Perfect choice for IQF (Individual Quick Freezing) processing.

Spiral Tunnel Freezer

The spiral tunnel freezer features a spiral conveyor design, saving floor space while offering large freezing capacity.

✔ Available in single-spiral and double-spiral multi-layer models.

✔ Ideal for large-scale continuous production.

✔ Commonly applied to bread, pastry, chicken nuggets, pizza, and packaged foods.

Tunnel type freezer

Spiral type freezer

Tunnel Freezer for Sale

If you are searching for a tunnel freezer for sale, AGICO offers a wide range of models tailored to your specific production capacity and product types. Each freezer is built with food-grade stainless steel, advanced refrigeration systems, and customizable configurations to suit your needs.

|

Model |

SSD1-300 |

SSD1-500 |

SSD1-1000 |

SSD2-2000 |

|

Throughput(kg/h) |

300 |

500 |

1000 |

2000 |

|

External Dimension L×W×H(mm) |

9000×2700×2007 |

11000×3400×2700 |

19000×3400×2700 |

19000×6600×2700 |

|

Feed Temperature(℃) |

+15 |

|

Discharge Temperature(℃) |

-18 |

|

Freezing Time(min) |

20–60 |

|

Cryogen |

R507/R404 |

Details of AGICO Tunnel Freezer

Freeze Fast

Rapidly freezing food while preserving its original color, flavor and texture. Strong freezing capability, simple operation and high level of automation.

We adopt heat fluctuation blowing method and ensure the fast freezing speed.

Get Tunnel Freezer Price Now!

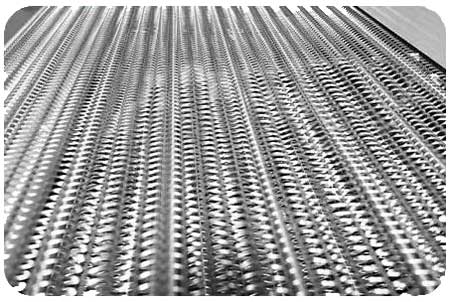

Mesh Belt of Tunnel Freezer for Sale

The tunnel freezer mesh belt is made of high-quality 304 stainless steel spring wire with a smooth surface, ensuring durability and hygiene. Equipped with an imported frequency converter, it offers stepless speed control for flexible and efficient freezing performance.

Get Tunnel Freezer Price Now!

Tunnel Freezer Warehouse Body

The tunnel freezer warehouse body is built with high-density polyurethane insulation and double-sided 304 stainless steel panels, delivering outstanding thermal efficiency, reliable hygiene standards, and easy cleaning for long-term, stable operation.

Get Tunnel Freezer Price Now!

Tunnel Freezer Cooling Fan

The cooling fan of tunnel freezer for sale features a variable blade pitch design, extending the defrosting interval and ensuring continuous, reliable production.

Get Tunnel Freezer Price Now!

Tunnel Freezer Price Influence Factors

When investing in a tunnel freezer, one of the most important considerations for food processors is the tunnel freezer price. The cost of a tunnel freezer can vary significantly depending on multiple factors, including equipment specifications, customization level, and production requirements. Below are the key elements that influence the final tunnel freezer price.

1. Freezing Capacity

The capacity of a tunnel freezer is one of the primary determinants of its price. Models can range from small-scale units handling hundreds of kilograms per hour to large industrial systems processing several tons per hour. Higher capacity machines require larger refrigeration systems, stronger conveyors, and more robust structures, which naturally increase the overall investment.

2. Design Type

The design type also affects the tunnel freezer cost. Standard straight-line belt tunnel freezers are generally more affordable, while customized designs such as spiral tunnel freezers or fluidized tunnel freezers come at a higher price due to their compact layout, larger freezing capacity within limited space, and advanced engineering complexity.

3. Refrigeration System

The choice of refrigeration system plays a major role in pricing. Buyers can choose between ammonia refrigeration (commonly used in large industrial plants for high efficiency and lower long-term cost) or Freon refrigeration (suitable for smaller installations with simpler maintenance). The type of refrigerant, compressor power, and cooling efficiency will directly impact the tunnel freezer price.

Tunnel freezer application

4. Automation Level

Modern food factories increasingly prefer automated freezing solutions. A basic tunnel freezer may only include manual controls, while advanced models can be equipped with PLC systems, touch-screen interfaces, frequency converters, automatic belt cleaning, and smart monitoring features. The higher the automation level, the more efficient and user-friendly the machine, but also the higher the investment cost.

5. Material & Construction Quality

Another factor influencing the tunnel freezer price is the choice of materials. AGICO uses high-quality stainless steel for all internal components, ensuring hygiene, durability, and easy cleaning. Stronger construction, better insulation panels, and reliable stainless steel fans all add to the cost but significantly improve long-term performance and lifespan.

6. Customization & Additional Features

Each food product has different freezing requirements. Some buyers may need ultra-low temperature models (up to –80ºC), special belt types (stainless steel belt or plastic chain belt), or compact footprint designs to fit into existing production lines. These customized solutions will affect the final tunnel freezer price but provide the best return on investment by improving efficiency and product quality.

AGICO provides competitive pricing with tailored solutions to help you achieve efficient, reliable, and cost-effective quick freezing for your food processing business.

Looking for a reliable tunnel freezer for sale? AGICO provides cost-effective tunnel freezers tailored to your production needs, including but limited to mesh belt tunnel freezer, spiral tunnel freezer, fluidized tunnel freezer, etc., with competitive price , customized solutions and global service support with professional installation and maintenance. Whether you are looking for a tunnel freezer for sale, comparing tunnel freezer price, or need a spiral freezer solution, AGICO provides a one-stop quick freezing solution for your food business.

Contact us now to get the latest tunnel freezer price and a free quotation and upgrade your food processing line with AGICO quick freezing solutions.

Get in Touch Now!

Tunnel type freezer

Tunnel type freezer Spiral type freezer

Spiral type freezer